+86 17727759177

inbox@terli.net

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2023-08-10 Origin: Site

Photovoltaic power generation, leveraging the photovoltaic effect at semiconductor interfaces, directly converts optical energy into electrical energy. This technology comprises three essential components: solar panels (modules), controllers, and inverters. These components, primarily composed of electronic elements, coalesce into an integrated photovoltaic power generation system.

With its distinctive advantages, solar energy has assumed the spotlight. Abundant solar radiation has emerged as a vital energy source, embodying traits such as boundless availability, pollution-free attributes, affordability, and unrestricted accessibility. Ground-level solar energy influx can reach remarkable levels of 800 MWhm per second. The captivating attributes of solar energy have fueled its growth trajectory since the 1980s.

At the core of photovoltaic power generation lies the photoelectric effect within semiconductors. Upon irradiation by photons, these semiconductors absorb energy and liberate electrons. When this liberated energy overcomes the binding forces within the atom, it forms an electric current. Silicon, with its four outer electrons, transforms into N-type semiconductors upon incorporation of five outer electrons from elements like phosphorus. Conversely, boron yields P-type semiconductors. The junction of P-type and N-type semiconductors generates a potential difference, giving birth to a solar cell. When sunlight hits the P-N junction, a current flows from the P-type to the N-type side.

The photoelectric effect, a pivotal phenomenon in physics, manifests when certain substances absorb energy from electromagnetic waves above a specific frequency, generating a current—optical electricity.

The production of polycrystalline silicon culminates in ingots, slices, and silicon wafers, which are then processed. Introducing trace amounts of boron and phosphorus onto the silicon wafer forms a P-N junction. Subsequent silk mesh printing, application of finely matched silver paste, sintering, back electrode application, and anti-reflective coating deposition complete the solar cell assembly. These cells are combined into modules, enveloped in aluminum casing with glass covering the front, and fitted with rear electrodes. Coupled with auxiliary devices, this forms a photovoltaic power generation system. DC-to-AC conversion necessitates an inverter, enabling power injection into the public grid or battery storage. Battery components typically account for 50% of system costs, with the remainder comprising converters, installation fees, auxiliary components, and other expenses.

Against the backdrop of limited conventional energy resources worldwide, solar energy emerges as a beacon. China's finite fossil fuel reserves pale in comparison to global averages, standing at a mere 10%. Solar energy, a replenishable, safe, noise-free, and pollution-free resource, is not confined by geographical constraints. Its applications span rooftops, regions with complex terrain, and more. Solar energy obviates the need for fuel consumption and on-site power generation, aligning well with long-term energy strategies.

Compared to conventional thermal power generation, photovoltaic power generation boasts several merits:

1:No inherent hazards

2:Utterly safe and reliable, devoid of noise and pollution

3:Impervious to geographical constraints, suitable for diverse locations

4:Fuel-independent, eliminating the need for on-site power generation

5:Offers high-quality energy

6:Emotionally accepted by users

7:Swift construction cycle and cost-effective energy generation

However, the production of solar panels can be energy-intensive and environmentally detrimental. Current solar panel manufacturing, while beneficial to the world, can exert pollution externally while contaminating domestically. Crafting a 1m x 1.5m solar panel necessitates burning over 40 kg of coal, whereas the most efficient Chinese thermal power plants can generate 130 kWh of electricity with the same amount of coal. Moreover, challenges include:

1:Low energy density requiring extensive land usage

2:Variable energy production based on meteorological conditions

3:Higher generation cost compared to thermal power

4:Environmentally unfriendly manufacturing processes for photovoltaic panels

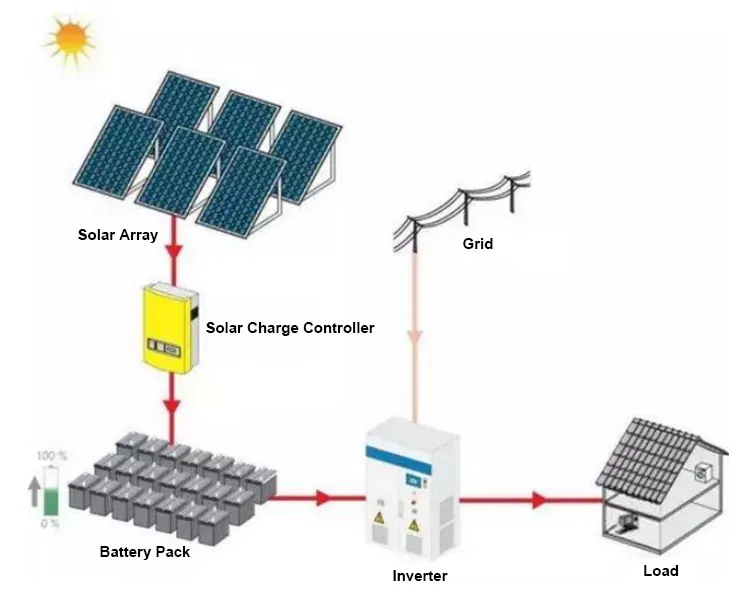

Standalone photovoltaic power generation, also known as off-grid photovoltaic power generation, is comprised of solar panels, controllers, and batteries. In cases requiring AC power, an inverter is essential. It serves applications like village power supply in remote areas, solar household power systems, communication signal power supply, cathode protection, and solar street lighting.

Grid-connected photovoltaic power generation transforms DC electricity from solar panels into AC electricity that meets municipal power grid standards via grid-connected inverters. This classification includes systems with and without battery storage.

Grid-connected systems with batteries offer adjustable features and can connect or disconnect from the power grid as needed. They can act as emergency backup during power outages. Such systems are often installed in residential buildings. On the other hand, grid-connected systems without batteries provide power scheduling and backup functions and are typically used for larger installations.

Distributed photovoltaic power generation entails small-scale photovoltaic systems at or near user sites to meet specific energy needs or bolster the existing power grid. It comprises components such as photovoltaic panels, brackets, DC junction boxes, grid-connected inverters, and AC power distribution cabinets. Operating under solar radiation, this system converts solar energy into DC power and adjusts the energy balance by connecting to the grid.