Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

If you want to spend less time cleaning your solar panels and keep them working well, you should look for a pv backsheet with strong resistance to dirt and weather. The right material helps your panels last longer and stay efficient. You need to think about your local climate, how long you want your system to run, cost, and if the backsheet matches your encapsulant. Your choice makes a big difference in performance.

Pick glass-backsheet or PVDF if you want less cleaning. These materials stop dirt and stains, so cleaning is simple.

Think about your weather when picking a backsheet. PVDF and glass-backsheet work well in hot and wet places.

Choose a strong backsheet to help your solar panels last longer. Good materials stop harm and keep panels working well.

Find a balance between cleaning often and how well panels work. Cleaning helps energy output, but too much can hurt the panels.

Make sure your backsheet fits your system and encapsulant. This helps your solar panels work well and last longer.

You want a pv backsheet that stays clean with little effort. Some materials resist dirt and stains better than others. Glass-backsheet stands out as the easiest to keep clean. Its smooth surface does not let dust or grime stick easily. You can often rinse it with water, and it will look almost new. PVDF (polyvinylidene fluoride) also works well for minimal cleaning. It has a slick surface that repels dirt and water. PVF (polyvinyl fluoride) offers good resistance to stains, but it may need a bit more attention than glass or PVDF. PET (polyethylene terephthalate) backsheets tend to attract more dust and can stain over time, so you might need to clean them more often.

Tip: If you live in a dusty or humid area, choose glass-backsheet or PVDF for the lowest cleaning needs.

Here is a quick comparison:

| Material | Dirt Resistance | Cleaning Frequency | Notes |

|---|---|---|---|

| Glass-Backsheet | Excellent | Rare | Smooth, easy to rinse |

| PVDF | Very Good | Low | Repels water and dust |

| PVF | Good | Moderate | Needs occasional cleaning |

| PET | Fair | Higher | Attracts dust, stains easily |

You want your solar panels to last and work well for many years. The pv backsheet you choose plays a big role in this. Glass-backsheet and PVDF both offer strong performance. They resist sunlight, heat, and weather changes. Glass-backsheet does not yellow or crack, even after years in the sun. PVDF also stands up well to UV rays and keeps its strength over time.

PVF gives you good performance, but it may not last as long as glass or PVDF in harsh sunlight. PET backsheets can lose strength when exposed to UV light. Studies show that PET can yellow and crack, especially if exposed to acetic acid or strong sunlight. This can lead to problems like delamination, where the layers start to peel apart. When the backsheet breaks down, your solar panel loses efficiency and may need repairs sooner.

Note: The stability of your pv backsheet is crucial for the long-term durability of your solar panels. If the backsheet fails, the whole module can lose power and need replacement.

Here is a summary of performance features:

| Material | UV Resistance | Durability | Common Issues |

|---|---|---|---|

| Glass-Backsheet | Excellent | Excellent | None reported |

| PVDF | Excellent | Excellent | Rare issues |

| PVF | Good | Good | May degrade over decades |

| PET | Fair | Fair | Yellowing, cracking, peeling |

When you choose a pv backsheet, think about how much cleaning you want to do and how long you want your panels to last. Glass-backsheet and PVDF give you the best mix of low cleaning needs and high performance. PVF works well in mild climates. PET costs less but may not last as long, especially in sunny places.

When you see a solar panel, the shiny top stands out. But the back is important too. The pv backsheet is the last layer on the back. It works like a shield for the inside parts.

The PV backsheet protects the solar panel’s parts. It helps the panel make energy without losing any. It must keep out water and handle hot or cold weather. It also blocks chemicals and stops damage. The backsheet gives insulation to the electrical parts.

Backsheets keep the electrical parts safe by giving insulation. This helps them last longer and lets the panel make power safely.

Backsheets are the outside layer of a solar panel. They are the first thing that faces tough weather.

You can think of the backsheet as a bodyguard for the panel. It keeps out water, dirt, and chemicals. It also stops electricity from leaking, which keeps things safe.

You might ask why the backsheet material matters. The answer is simple. The right material helps your solar panels work better and last longer.

Good backsheets protect against bad weather and damage. This makes them last longer.

Bad materials can break and make the panel less efficient.

Good backsheets help solar panels last a long time, even over 30 years.

You can pick from different backsheet materials. Each one has good and bad points:

Polyvinyl Fluoride (PVF): Used in over 35% of panels. It is strong and resists sunlight well.

Polyester (PET): Used in almost 30% of panels. It is cheap and works well but needs extra weather protection.

Polyethylene (PE): Used in less than 10% of panels. It is light and bends easily, mostly for cheaper panels.

Polyimide: More people want it for special uses. It costs more but is very stable.

Other advanced materials: These are new and made to be recycled.

If you pick the right backsheet, your solar panels will last longer and work better. If you pick the wrong one, you may need to clean or fix your panels more often. You might even have to replace them sooner.

Image Source: pexels

You often see PET used in solar panels because it is affordable. PET gives moderate resistance to weathering, but it needs extra protection to last in tough climates. This material can attract dust and may stain over time. PET does not handle UV rays as well as other options. Over the years, PET can yellow, crack, or peel, especially in hot or sunny places. You may notice more cleaning and repairs with PET. PET works with common encapsulants like EVA, but you must watch for delamination and discoloration.

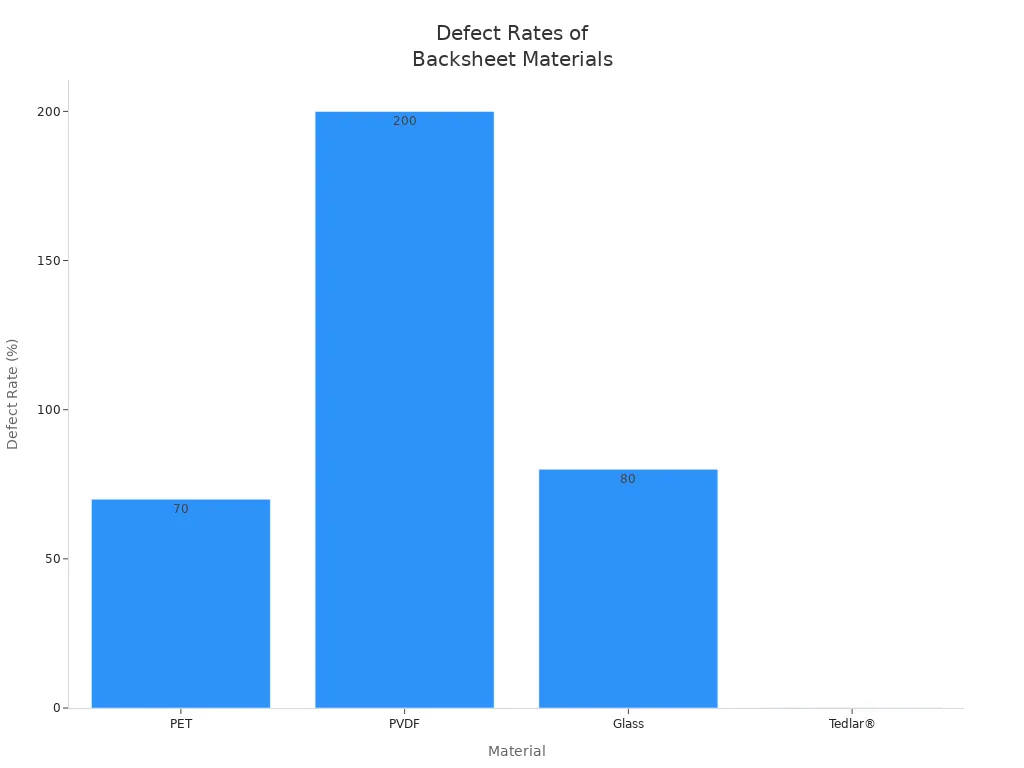

PVF, also known as Tedlar®, stands out for its high resistance to weathering. You can expect PVF to last over 20 years, even in harsh outdoor conditions. This material resists dirt and stains better than PET. PVF also blocks UV rays and keeps its strength for a long time. You will find PVF compatible with most encapsulants, which helps prevent problems like delamination. PVF has a very low defect rate, making it a reliable choice for your pv backsheet.

PVDF offers performance similar to PVF. It resists weathering, UV rays, and dirt very well. PVDF keeps its surface slick, so dust and water do not stick easily. You can use PVDF in places with strong sunlight or heavy rain. PVDF works well with standard encapsulants, and it rarely shows issues like cracking or peeling. This makes PVDF a strong option for long-lasting panels.

Glass-backsheet gives you the smoothest surface, which makes cleaning easy. Dust and grime do not stick, so you spend less time on maintenance. Glass does not yellow or crack under UV light. It also resists weather changes and moisture. You can use glass-backsheet in extreme climates, such as deserts or tropical areas. Glass works well with most encapsulants, but you should check for compatibility with your specific panel design.

Tip: Co-extruded backsheets and glass-backsheets help reduce problems like delamination and cracks, especially in tough environments.

Here is a quick comparison:

| Material | Resistance to Weathering | Notes |

|---|---|---|

| PET | Moderate | Needs extra protection |

| PVF | High | Lasts 20+ years |

| PVDF | High | Similar to PVF |

| Glass | Excellent | Easy to clean, durable |

You can see how these materials compare in long-term defect rates:

When you choose a pv backsheet, think about your climate and how much maintenance you want to do. PVF and PVDF give you strong protection and low cleaning needs. Glass-backsheet works best if you want the easiest cleaning and top durability.

Image Source: pexels

You might wonder how often you need to clean your solar panels. The answer depends on your local environment and the type of backsheet you choose. Dust, pollen, and pollution can build up on your panels and block sunlight. When this happens, your panels make less energy. If you clean your panels regularly, you can restore their power output to almost new levels. However, cleaning too often can cause scratches or other damage to the surface.

Studies show that the type of solar cell and backsheet can change how much dirt affects your system. Poly-Si modules lose more power from dust than CdTe modules. Poly-Si panels can lose up to 15% of their energy from soiling, while CdTe panels lose about 13%. Soiling also makes your panels hotter, which can lower their efficiency even more. You should find a balance between cleaning enough to keep your panels working well and not cleaning so much that you wear them out.

Tip: Choose a pv backsheet that resists dirt and is easy to clean. This helps you keep your panels efficient without extra work.

You want your solar panels to last for many years. The materials you pick for your panels, especially the backsheet and encapsulant, play a big role in how much power your system will make over time. Some backsheets, like EVA-PPF, can lose up to 12% of their power after long exposure to heat and moisture. Others, with better combinations of materials, may only lose 2% under the same conditions.

EVA-PPF modules: Up to 12% power loss after 4000 hours of damp heat.

EVA-PPF (improved): Only 2% loss under similar conditions.

The right backsheet and encapsulant can help your panels keep more of their original power.

If you pick a high-quality backsheet, you will see less power loss over the years. This means you get more energy and value from your solar system.

Think about your local weather before picking a backsheet. Hot, wet, or dirty air can damage solar panels faster. Moisture can cause rust and make parts break. Pollution and chemicals in the air can hurt the panel. Sunlight can make the backsheet crack or peel as time goes on.

Some backsheets work better in tough places. Polyolefin-based backsheets last longer and are better for the planet than PET-based ones. They help your panels make more energy and stay reliable. If you live where it is very humid, choose hydrolysis-resistant PET. In sunny places, double-fluorinated backsheets protect better from sunlight.

Tip: Pick a backsheet that matches your weather. This helps your panels last longer and work well.

Think about how your choice affects the planet. How a backsheet is made and recycled matters. Polyolefin backsheets are better for the environment during their life.

Each solar system needs different things. Think about how long you want your system to last, how much money you want to spend, and what type of setup you have. Here are some things to think about:

How long you want your panels to last is important. If you want them to last many years, pick a backsheet that can handle weather and sunlight.

Studies show backsheets can wear out over time. Choose one that fits how long you want your system to work.

Wet air, pollution, and sunlight can cause rust, peeling, and less power. Pick a backsheet that protects against these problems.

Match your backsheet to your system's voltage and use. The table below shows what to look for:

| Requirement | Consideration |

|---|---|

| Environmental Conditions | High Humidity: Use hydrolysis-resistant PET |

| High UV Exposure: Double-fluorinated backsheets | |

| System Voltage | 1000V: Minimum DTI of 150μm |

| 1500V: Minimum DTI of 300μm | |

| Specific Applications | Portable: Lightweight, strong backsheets |

| Agricultural: Needs ammonia resistance | |

| Rooftop: Needs fire safety and support |

Think about the encapsulant inside your panel too. EVA is used most often. It sticks well and lets light pass through. POE is getting more popular because it keeps out water and helps stop power loss. Both work with many backsheets, but always check if they fit together. New types like coextruded EPE can save money and keep good results.

Note: If you use special modules or new cell tech, you may need a special encapsulant and backsheet together.

When you pick a pv backsheet, match it to your weather, system needs, and encapsulant. This helps your solar panels last longer and work better.

If you pick a pv backsheet made of glass or PVDF, you will get the best results. These materials do not need much cleaning and work very well.

Glass and copper backsheets help keep panels cool. They also help them work better.

Experts say you should pick a backsheet that fits your weather and how you set up your panels.

CPC backsheets can change to fit different places by using different coatings and thickness.

| Future Trend | Impact |

|---|---|

| Smart backsheet technology | Makes cleaning easier and helps panels last longer |

| Nanotechnology integration | Helps panels resist UV and heat better |

Talk to a solar expert about UV resistance, how panels handle heat, and if they are certified before you choose.

Glass-backsheet needs the least cleaning. Its smooth surface keeps dust and dirt from sticking. You can rinse it with water, and it looks clean again.

No. You should pick a backsheet made for your climate. PVDF and glass-backsheet work best in hot or humid places. They resist moisture and sunlight better than PET or PVF.

Yes. The backsheet protects your panel from weather and damage. If you choose a strong backsheet like PVDF or glass, your panels last longer and work better.

Always check the manufacturer’s guide. Most backsheets work with EVA or POE encapsulants. Some new materials may need special backsheets. Ask your installer for help.

Not always. You should match the backsheet to your needs and climate. Sometimes, a mid-priced option like PVF gives good value and performance for mild weather.

Backsheet Silicone Coating: A Solution for Enhanced PV Module Protection and Easier Cleaning

How PV Module Backsheets Impact Cleaning Requirements and System Longevity

Shingled Technology vs. Half-Cut Cells: Which Solar Panel Design Delivers Superior Performance?

What is MBB? Defining Multi-Busbar Technology in Half-Cut Solar Panel Manufacturing

SMBB Technology in Half-Cut Solar Cells: How Smart Multi-Busbar Design Improves Power Output

Amorphous Silicon PV Cells: Applications, Advantages, and Limitations of This Thin-Film Technology

From Cell to Module: The Manufacturing Process and Material Considerations in PV Production