Views: 0 Author: Site Editor Publish Time: 2025-06-07 Origin: Site

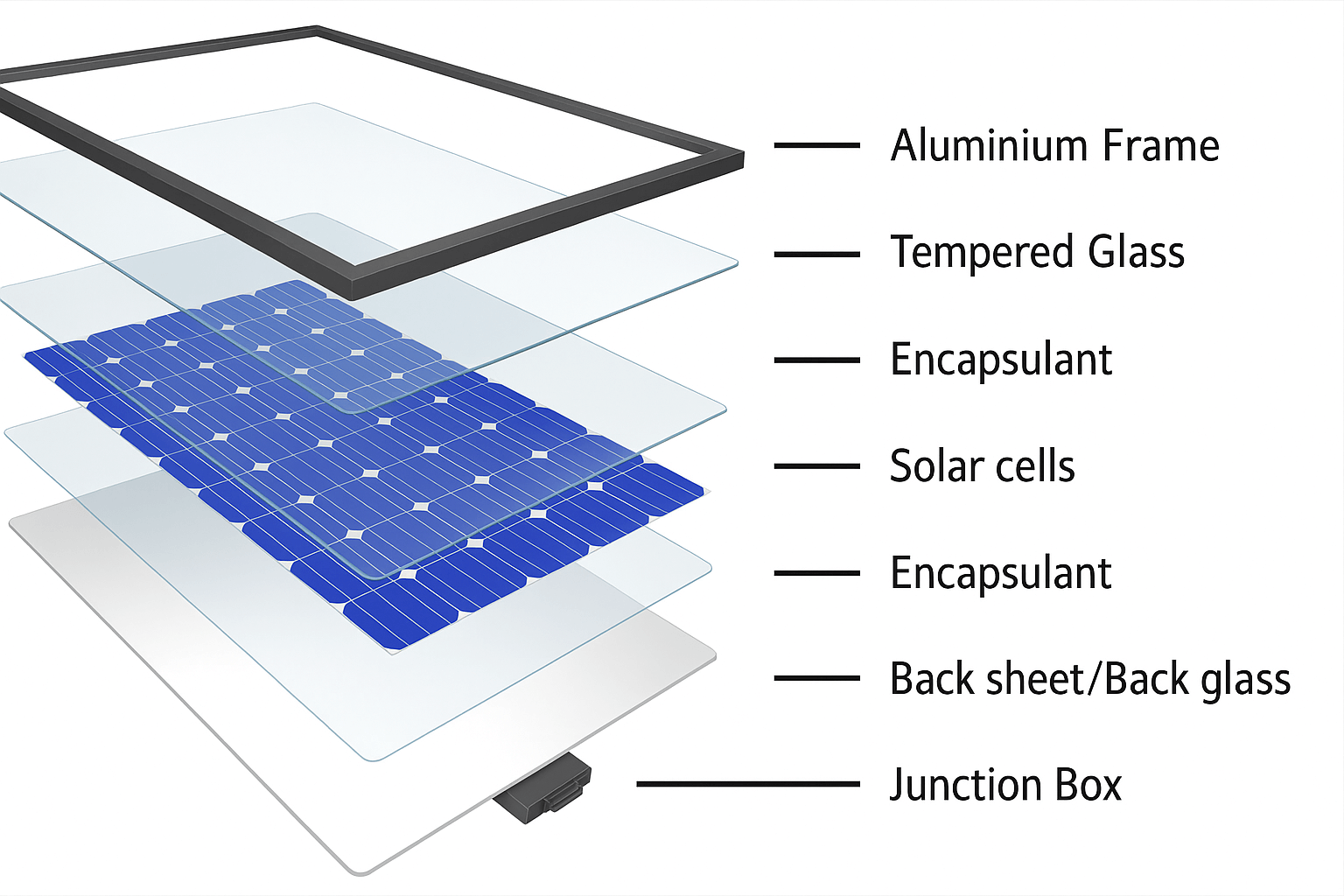

Solar panel materials play a crucial role in converting sunlight into energy. Silicon is essential due to its excellent electrical conductivity. Metals such as aluminum and copper provide structural support and assist in electricity transmission. Glass enhances the durability of the panels and safeguards the internal components. Protective films are applied to the panels to shield them from weather conditions and potential damage.

Innovative materials like thin-film and perovskite cells are enhancing the efficiency and reducing the costs of solar panels. Concepts such as bifacial panels and tracking systems have significantly boosted energy production by up to 57%. This demonstrates the industry's commitment to continuously improving solar panel materials and technology.

Silicon is the key material in solar panels. It turns sunlight into electricity very well.

Aluminum gives support to the panels and handles heat. It is light and good for the environment.

Copper helps electricity move inside the panels. Its use is growing as renewable energy becomes popular.

Glass protects the parts of solar panels. It lets sunlight through and makes panels last longer.

Encapsulation films, like EVA, keep solar cells safe from water and sunlight damage. This helps them work longer.

Recycling materials like aluminum and silver cuts down on waste. It also saves energy during production.

New technologies, like PERC and HIT cells, make panels work better. They don’t need big changes to how panels are made.

Solar manufacturing focuses on being eco-friendly. It aims to lower harm to nature and reuse materials.

Silicon is vital for making solar panels. It changes sunlight into electricity very well. Silicon is one of Earth's most common elements. It is cleaned and turned into pure crystalline silicon for solar cells. People use it because it works well, lasts long, and costs less.

Monocrystalline silicon is the best type for solar panels. It is made from one solid crystal. This helps electrons move easily, making it very efficient. These panels are black and work great for high-performance needs.

Polycrystalline silicon is made by melting many silicon pieces together. It is cheaper and easier to make than monocrystalline silicon. These blue panels are often used for homes and businesses. They balance cost and efficiency.

Amorphous silicon is a soft, non-crystal type used in thin-film panels. It is light and bendable, good for portable solar devices. But it is less efficient, so it’s not used much for big solar projects.

PERC cells are a big step forward in solar technology. They have a special layer that reflects light inside the cell. This makes them lose less energy and produce 6-12% more power. PERC cells are popular because they improve efficiency without big changes in production. More information about PERC vs IBC solar panel technology.

HIT cells mix crystalline silicon with thin layers of amorphous silicon. This design makes them more efficient and less affected by heat. HIT cells also work better in dim sunlight, making them useful in cloudy areas.

Polysilicon is a key material for solar panels. It is made from raw silicon and turned into pure crystalline silicon. The need for polysilicon is growing as solar energy becomes more popular. In 2022, over 873,000 metric tons of polysilicon were made to meet demand.

China makes most of the world’s solar panels and polysilicon, about 70%. This is due to new technology and government support for clean energy. The U.S. has also grown its solar panel production, reaching 31 gigawatts recently. But changing polysilicon prices affect costs for manufacturers everywhere.

Metals are very important in making solar panels. They help with strength, electricity flow, and making panels work better. Aluminum, copper, and silver are the main metals used.

Aluminum is the main support for solar panels. It is light but strong, holding parts together and standing up to wind and rain. It also helps cool the panels by spreading heat, keeping them efficient.

Tip: Because aluminum is light, it’s easier to move and set up. This saves money and energy during installation.

Aluminum can be recycled, making it a great eco-friendly choice. Old solar panels can be melted down, and the aluminum reused for new panels or other products. This process saves water and reduces waste, helping the planet.

Making 1 MW of solar power needs about 21 tons of aluminum.

By 2050, solar panels will need 160 million more tons of aluminum.

Recycling aluminum uses much less water than making new aluminum.

Copper moves electricity inside solar panels. It’s used in wires and busbars to carry power efficiently. Big solar farms need about 2,500 kg of copper for every MW of energy they produce.

As the world uses more green energy, the need for copper grows. The IEA says solar panels will need more copper, from 756.8 kilotons in 2022 to 2,062.5 kilotons by 2035. This shows how important copper is for clean energy.

Note: Copper helps save energy and lowers CO2 emissions, making it great for the environment.

Silver makes solar cells work better by helping convert sunlight into energy. It’s used as a paste on the cells to collect electricity and improve performance.

Silver is expensive and not easy to find. It makes up about 10% of the cost of solar panels, and this could rise. By 2025, solar panels may need 156 million ounces of silver, or 15% of the world’s supply. New ways to use less silver while keeping efficiency are being developed.

The market for silver paste in solar cells may grow 7.7% yearly from 2025 to 2032.

By 2050, solar panels might need 332 million ounces of silver for new projects.

Image Source: pexels

Solar glass is important for solar panels. It protects parts inside and helps sunlight pass through. These features make solar panels work better and last longer.

Solar glass lets sunlight in but blocks harmful UV rays. A special coating keeps the glass clear while stopping too much heat. This coating helps solar panels work well in different weather. Spectral selectivity allows sunlight through but blocks unwanted energy. These features improve solar panel performance.

| Feature | Description |

|---|---|

| Solar Control Coating | Thin, clear layer that limits heat but lets sunlight in. |

| Solar Heat Gain Coefficient (SHGC) | Shows how much heat passes through, with lower numbers meaning better insulation. |

| Spectral Selectivity | Lets visible light in while blocking extra heat energy. |

Solar glass is strong and handles wind, rain, and temperature changes. Its coating lasts a long time and keeps the glass clear. Self-cleaning features make it easier to maintain. These qualities make solar glass a key part of solar panels.

| Property | Description |

|---|---|

| Durability | Built to last and resist tough weather conditions. |

| Optical Transparency | Stays clear and cleans itself to reduce upkeep. |

| Application Methods | Can be added in different ways for flexibility. |

Solar glass helps solar panels absorb more sunlight. This boosts energy production and lowers cooling costs in summer. Studies show solar coatings can reduce indoor heat by up to 14.7%. Solar glass is essential for making solar panels efficient.

| Study | Findings |

|---|---|

| Pereira et al. | Coatings lower indoor heat by 7.1% in winter and 14.7% in summer. |

| Nagahama et al. | Coatings improve comfort and cut cooling costs. |

Solar glass makes panels strong and protects them from damage. It keeps solar cells working well over time. Its strength and clarity make it a must-have material for solar panels.

Tip: Solar glass boosts efficiency and cuts maintenance costs, making it a smart, long-term choice.

Encapsulation films are key parts of solar panels. They protect solar cells from weather, make panels last longer, and improve how well they work. These films block moisture, UV rays, and physical damage, helping solar panels perform well for many years.

EVA is a common material in solar panels because it protects well. It keeps moisture and dirt away from solar cells, keeping them working. During production, EVA hardens into a strong structure. This makes the solar panel parts stick together better and last longer.

Different ways of heating EVA during production can change how well it works over time. For example, higher or lower heat can affect how much energy the panel loses as it ages. EVA’s flexibility makes it a trusted choice for solar panel makers.

| Feature | Details |

|---|---|

| Protection Role | EVA blocks harmful elements like water and dirt. |

| Heating Process | Heat levels affect how long panels stay reliable. |

| Hardening Reaction | Creates strong bonds for better durability. |

| Performance Changes | Heat settings impact energy loss over time. |

EVA lets lots of sunlight reach the solar cells, helping them make more energy. It also sticks well to other materials, keeping the panel strong. EVA works well with many solar parts, making it a popular choice for manufacturers.

| Film Type | Key Features |

|---|---|

| EVA | Great sunlight passing, strong bonds, and good material fit. |

| POE | Blocks water well but may have issues with additives over time. |

Backsheet materials are important for keeping solar panels safe and strong. They stop electricity from leaking out and protect the solar cells. This makes the panels work safely and efficiently. Backsheets also give support, helping the panels stay strong under pressure.

| Feature | Details |

|---|---|

| Electrical Safety | Stops electricity from escaping into the environment. |

| Physical Support | Keeps panels strong even under stress. |

| Weather Protection | Blocks UV rays, water, and extreme temperatures. |

Backsheets help control heat in solar panels, stopping them from getting too hot. They also protect against rust caused by water and sunlight. Built to last over 20 years, backsheets are key to making solar panels durable.

Backsheets reduce heat stress in solar panels.

They act as barriers, protecting against extreme heat.

Backsheets control how much heat panels absorb, avoiding overheating.

They keep electricity flowing safely and prevent short circuits.

Encapsulation films and backsheets are vital for solar panels. They protect, insulate, and improve performance, helping panels last longer and work better.

Auxiliary parts are key to making solar panels work well. These include junction boxes, welding tape, and silicone. Each part helps solar cells perform better during production and use.

The junction box connects all the wires in a solar panel. It stops electricity from leaking and stays strong in tough weather. Plastic junction boxes are light and insulate well, making them great for homes and businesses. Metal ones, like aluminum or steel, are tougher and handle heat better, perfect for harsh conditions.

Note: In 2023, IP65 junction boxes made up 42.5% of sales. They are affordable and work well outdoors. IP66 boxes are becoming popular for better dust and water protection.

Junction boxes keep solar cells safe by stopping short circuits. They are built to handle impacts and bad weather, ensuring they work reliably. New materials and designs now let them carry more electricity, improving safety and efficiency.

Welding tape links solar cells and helps electricity move smoothly. Its quality affects how well solar panels work and last. Making the tape cover more area can boost the power solar cells produce.

Reflective welding tape helps sunlight reach solar cells better.

Tests show welding tape stress is a big factor in production, second only to pressure on silicon cells.

Good welding tape is strong and conducts electricity well. High-quality tape ensures solar panels convert energy efficiently. This makes it a must-have for building solar panels.

Silicone is used to stick and seal parts of solar panels. RTV silicone sealant is very durable, protecting against water, UV rays, and extreme heat or cold. This keeps solar cells working longer.

Silicone bonds and seals different parts of solar panels. It’s flexible and handles weather well, keeping panels strong. Silicone helps panels last through tough conditions while working at their best.

| Evidence Description | Impact on Performance |

|---|---|

| Dual-axis solar tracking improves energy yield by maintaining optimal irradiance angles. | Increases overall efficiency of CPV-T systems. |

| Integration of reflective mirrors with tracking mechanisms enhances concentrated solar flux distribution. | Significant gains in energy output. |

| Custom CPV-T testbed with three coaxial mirrors shows 500% improvement in thermal power stability. | Ensures sustained thermal output under varying conditions. |

Auxiliary parts like junction boxes, welding tape, and silicone are crucial. They make solar panels safer, stronger, and more efficient. Their smart designs and reliable performance help solar energy systems succeed.

Sustainability is crucial in making solar panels. It helps reduce harm to the environment while improving efficiency. Companies are finding new ways to recycle, cut waste, and use eco-friendly methods. These efforts support global goals to fight climate change.

Aluminum is easy to recycle and widely used in solar panels. Recycling it saves energy, water, and reduces the need for mining. New recycling methods recover up to 98% of aluminum from old panels. This lowers costs and meets the rising demand for aluminum, expected to grow by 160 million tons by 2050.

Silver is key to making solar cells work better, but it’s scarce. Recycling can recover 98% of silver, cutting water use by 60% and keeping its value. Silicon and glass are also reclaimed using heat and separation methods, with recovery rates up to 95%. These steps reduce waste and make manufacturing more sustainable.

Solar panel makers now use greener materials to lower their carbon footprint. Thin-film panels create less pollution than traditional ones but need careful handling of toxic parts. Polycrystalline panels are simpler to make and have a smaller carbon footprint, making them a better choice for the environment.

Tip: Closed-loop systems in factories can cut water use by 90%, boosting sustainability.

New technologies are making solar panel production more efficient. These methods save 10-30% of energy during manufacturing. Supply chains are checked to meet eco-friendly standards. Recycling and reusing materials at the end of a panel’s life reduce waste and support a circular economy.

| Sustainability Metric | Impact Description |

|---|---|

| Carbon Emissions Reduction | Cuts greenhouse gases from making solar panels. |

| Energy Efficiency | Saves 10-30% of energy during production. |

| Water Consumption | Closed-loop systems reduce water use by up to 90%. |

| Supply Chain Sustainability | Ensures materials and processes are eco-friendly. |

| End-of-Life Management | Focuses on recycling and reusing old materials. |

A circular economy is changing how solar panels are made. Materials like silicon, glass, and aluminum are reused instead of being thrown away. Tools like PV ICE from NREL help track and improve recycling. These practices cut landfill waste and create materials for new panels.

Future solar materials aim to be greener while staying efficient. Solar energy already has a much smaller emissions footprint than coal or gas. New non-toxic materials for thin-film panels are being developed to improve sustainability.

Note: Making solar panels last 2-3 years longer could cut waste by 2-3 million metric tons by 2050. Durability and repairability are key to reducing waste.

Solar panels are made using materials like silicon, metals, glass, and films. These materials help panels last long and work efficiently. They also support the process of making solar panels. The solar industry is improving by using greener methods and smart designs. These changes aim to lower costs and protect the environment. Experts study ways to make solar energy cheaper and more sustainable. Their work shows a future where solar power is easier to afford and better for the planet.

| Key Outputs | Description |

|---|---|

| Minimum Sustainable Prices | Lowest possible prices for making solar panels in eco-friendly ways. |

| Step-by-Step Manufacturing Costs | Clear list of costs for each part of the production process. |

| Cost Reduction Roadmaps | Plans to lower the costs of making solar panels over time. |

Silicon is the main material in solar panels. It turns sunlight into electricity well. It is common, strong, and affordable, so manufacturers like using it.

Aluminum supports the panels and spreads heat evenly. It is light, strong, and can be recycled, making it a green choice for frames.

Glass protects the inside parts and lets sunlight through. It is strong and blocks UV rays, helping panels last longer and work better.

Encapsulation films protect solar cells from water, UV rays, and damage. They make panels stronger and help them work well for years.

Silver helps solar cells carry electricity better. It improves how sunlight turns into energy, making it key for efficient panels.

Yes, materials like aluminum, silicon, and glass can be reused. Recycling cuts waste, saves energy, and helps make solar panels greener.

Copper moves electricity inside solar panels. It is used in wires and busbars to make power flow smoothly.

They use green materials, recycle parts, and save energy during production. These steps lower harm to the environment and support recycling.