Views: 0 Author: Site Editor Publish Time: 2025-06-03 Origin: Site

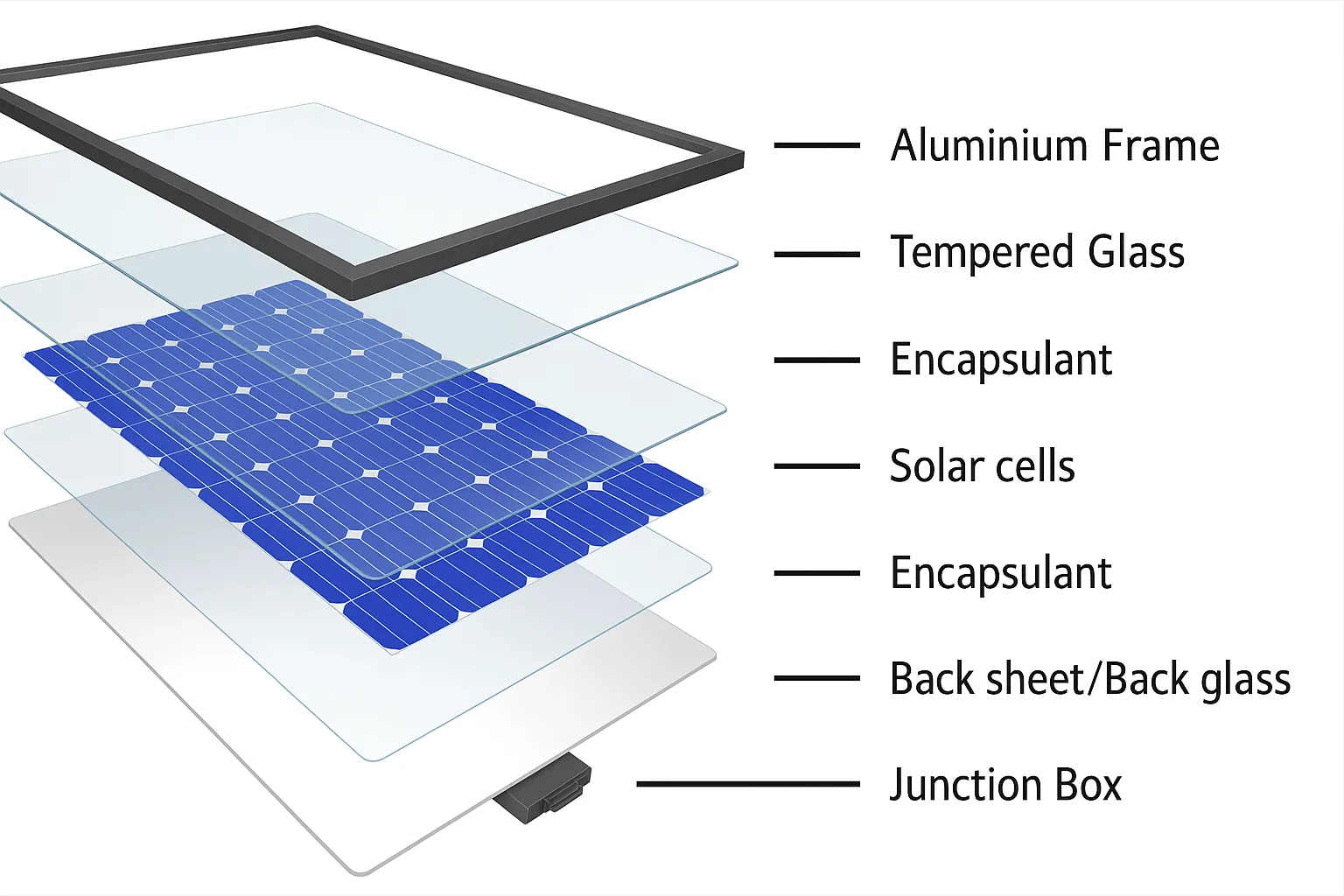

Solar panels have changed how we use renewable energy. These amazing systems turn sunlight into electricity using key parts. Each part of a solar panel is important for working well and lasting long. For example, solar cells take in sunlight to make electricity. Other layers, like encapsulation films and backsheets, protect and insulate the panel.

More people around the world are using solar panels. In 2020, solar power grew by 22%, making up 3.1% of global electricity. By 2050, experts think this could grow to 50%. This shows how powerful solar energy can be. As technology improves, knowing the main parts of solar panels helps us make better energy choices.

Solar panels turn sunlight into electricity using parts like solar cells, films, and glass.

Solar cells are key for making energy. Some work better than others. Monocrystalline cells work best but cost the most.

Encapsulation films keep solar cells safe and make them last longer. They must be applied correctly to work well.

The glass layer protects solar cells from damage. It also lets sunlight pass through easily.

A strong backsheet stops water and dirt from harming the solar cells. It helps the panel last longer and stay safe.

The frame holds the solar panel together. It keeps it steady during bad weather.

The junction box links electrical parts and keeps them safe from weather. This helps energy flow smoothly.

Good connectors and wires lower energy loss. They also make the solar panel system work better.

Image Source: pexels

Solar cells, called photovoltaic cells, turn sunlight into electricity. They use the photovoltaic effect, where sunlight hits silicon atoms. This releases electrons and creates an electric current. Solar cells are key to powering homes, businesses, and industries in a green way.

How well a solar panel works depends on its efficiency. A panel with 20% efficiency can make about 200 kWh yearly if conditions are perfect. Things like sunlight strength, electron movement, and light reflection affect this rate. New tech, like PERC cells, boosts efficiency by bouncing back unused sunlight and cutting heat loss.

Different solar cells have unique benefits, costs, and lifespans. Knowing these differences helps you pick the best one.

Monocrystalline Silicon (m-si):

These cells work very well, with efficiency between 15% and 24%. They last up to 25 years and are stable for long-term use. But they cost more to make and can react to temperature changes.

Polycrystalline Silicon (p-si):

These cells are cheaper and easier to produce, with efficiency from 10% to 18%. They absorb sunlight well but don’t work as efficiently as monocrystalline cells. They also react more to temperature changes.

Gallium Arsenide (GaAs):

These cells are the most efficient, with rates between 28% and 30%. They handle temperature changes well and are very durable. However, they are extremely expensive and not practical for most users.

| Solar Cell Type | Efficiency Range | Lifespan | Advantages | Restrictions |

|---|---|---|---|---|

| Monocrystalline Silicon (m-si) | 15 ÷ 24% | 25 years | Stable, high performance, long-lasting | Expensive, reacts to temperature changes |

| Polycrystalline Silicon (p-si) | 10 ÷ 18% | 14 years | Affordable, easy to make, absorbs sunlight | Less efficient, reacts more to heat |

| Gallium Arsenide (GaAs) | 28 ÷ 30% | 18 years | Very efficient, handles heat well, durable | Very costly |

Solar cells are the main part of a solar panel. They change sunlight into electricity, which affects how much energy the system makes each year. Home solar panels can reach 24% efficiency, while lab-made cells have hit 47.6%.

The design and materials of solar cells affect how well they work. Things like quantum efficiency and voltage show how sunlight becomes electricity. Current and voltage curves help find the maximum power a cell can produce. This info is important for checking your panel’s energy output.

New ideas, like Oxford PV's perovskite modules, have raised efficiency to 24.5%. These panels make 20% more energy than regular silicon ones. These improvements make solar cells a smart and eco-friendly choice for energy needs.

Encapsulation films help solar panels last longer and work better. These films protect solar cells from things like water, dirt, and sunlight damage. They keep the cells safe by sealing them off from harmful outside elements. This helps the panel make steady energy over time.

These films also make the solar panel stronger. During assembly, they stick the solar cells to layers like glass and backsheets. This connection gives support and stops the layers from peeling apart. If peeling happens, the panel’s energy-making ability can drop.

Tip: Applying encapsulation films correctly is important. Mistakes like bubbles or uneven layers can lower the panel’s performance.

The materials used for encapsulation films affect how strong and efficient the solar panels are. Two popular materials are Ethylene Vinyl Acetate (EVA) and Polyolefin Elastomer (POE).

EVA: This material is cheap and clear. It sticks well and bends easily but can turn yellow after long exposure to sunlight.

POE: This material resists heat and sunlight damage better than EVA. It works well in tough conditions and lasts longer.

Tests show POE is stronger than EVA when it comes to resisting damage. Scientists use special tests to check how well these materials hold up, like heat analysis and light tests. POE performs better in extreme conditions.

| Material | Encapsulation Method | Thickness | Testing Temp. (°C) | Lifetime at 37 °C (Years) |

|---|---|---|---|---|

| Polyimide | Spin | 10 μm | 75 | 2.52 |

| Parylene C | CVD | 10 μm | 75 | 4.46 |

| Silicone Elastomer (+Parylene C) | Dip (+CVD) | 5 mm + 40 μm | 85 | 6.3 |

Encapsulation films are key to keeping solar cells safe. They block water from getting inside, which can ruin the cells. Materials like silica and alumina are great at stopping water and help the cells last longer.

Newer films with better water-blocking abilities make solar cells even more stable. This is especially helpful for delicate types like perovskite cells. Some films also manage heat, keeping panels cool so they don’t lose power from overheating.

Applying these films carefully is very important. Bad application can cause bubbles or peeling, which weakens the protection. Adding water-repelling features to the films can make them even better at keeping the cells safe and working well for years.

Note: Scientists are always improving encapsulation films. These new materials make solar panels stronger and more useful for different needs.

Solar panel glass is the first shield for the panel. It protects the fragile solar cells from rain, hail, and dust. This glass lets sunlight pass through while reducing reflection. This helps the panel absorb more energy. Without this layer, the panel would not last as long or work as well.

The glass is made to handle tough weather like heat, cold, and wind. Its strength helps the panel work well in harsh conditions. By keeping the inside parts safe, the glass makes the system more reliable and long-lasting.

Solar panels use different glass types to improve strength and performance.

Tempered Glass: Strong and affordable, it breaks into safe pieces.

Low Iron Oxide Glass: Lets more sunlight reach the solar cells for better energy.

Anti-Reflective Coated Glass: Cuts down reflection and boosts energy conversion.

Fractal Glass Textured Surface: Reduces reflection and improves power output.

| Type of Glass | Key Features | Uses |

|---|---|---|

| Tempered Glass | Strong, safe when broken | Front layer of solar panels |

| Low Iron Oxide Glass | Allows more sunlight through | High-efficiency solar panels |

| Anti-Reflective Coated Glass | Lowers reflection, increases efficiency | Improves panel performance |

| Fractal Glass Textured Surface | Reduces reflection, boosts optical and electrical efficiency | Advanced solar panels |

Good solar panel glass improves how well the panel works and lasts. Thicker glass is stronger and less likely to break. It protects the solar cells from hail and other damage.

Special glass, like low iron oxide glass, lets in more sunlight. Anti-reflective coatings help by reducing sunlight bounce-back. This means more light reaches the cells to make energy. Studies show adding special materials to glass can increase energy capture in cities.

Durability is also very important. Thick glass handles temperature changes better and avoids cracks over time. This keeps the panel working well, even in bad weather. Using strong glass lowers repair costs and makes the panel last longer.

Note: Textured glass reduces glare and improves efficiency. This makes it great for crowded city areas, helping more people use solar power.

The backsheet is the layer at the back of a solar panel. It protects the inside parts, like solar cells and films, from outside damage. It stops water, dirt, and other harmful things from getting in. This keeps the panel working well for many years.

It also helps with insulation. The backsheet blocks electrical problems and keeps energy flowing safely. It protects the solar cells from very hot or cold temperatures. This lowers the chance of losing power because of overheating or freezing.

Tip: A strong backsheet makes your solar panel last longer and work better.

Different materials are used to make backsheets, each with its own benefits:

Fluoropolymers: These are tough and resist UV rays and heat. They stay strong even in bad weather.

Polyethylene Terephthalate (PET): This is cheaper but doesn’t last as long as fluoropolymers.

Glass: Rarely used, but it’s very durable and found in double-glass panels.

Tests show how these materials perform:

| Material Type | Power Loss | Variability | Field-Proven Performance |

|---|---|---|---|

| DuPont TM Tedlar® PVF | Low | Stable | Over 30 years |

| Glass | High | Unstable | Less than 6 years |

| Polyethylene Terephthalate | High | Unstable | Less than 6 years |

Fluoropolymers, like DuPont TM Tedlar®, are trusted for lasting performance. They are often used in top-quality solar panels.

The backsheet is important for keeping the solar panel safe and working well. It blocks water, UV rays, and physical damage. This stops rust and wear that could cause electrical problems.

It also keeps the films inside dry by stopping water from getting through. This protects the solar cells and keeps the panel making energy. Its ability to handle heat and cold helps the panel last longer without breaking.

Benefits of a good backsheet include:

Temperature Control: Protects solar cells from extreme heat or cold.

Electrical Safety: Stops interference for smooth energy flow.

Physical Protection: Shields the panel from impacts and damage.

UV Defense: Blocks harmful rays to prevent wear.

Water Barrier: Keeps the inside dry to avoid problems.

Choosing a solar panel with a strong backsheet means better performance and fewer repairs over time.

The frame of a solar panel gives strong support. It holds all parts together and keeps the panel steady. Without a good frame, the panel might bend or break. Frames also spread weight evenly, protecting the roof or mount.

Problems like water pooling or weak spots can harm roofs. This shows why a strong frame is so important. A sturdy frame keeps the panel safe and prevents damage. Checking the roof or mount before installing can stop future issues.

The materials for solar panel frames affect their strength and cost. Common options are aluminum, stainless steel, and composite materials.

| Material Type | Key Properties | Applications |

|---|---|---|

| Composite Materials | Strong, flexible, lightweight, resists rust | Custom solar panel frames |

| Aluminum | Light, resists rust, affordable | Homes and businesses |

| Stainless Steel | Very strong, handles tough weather, lasts long | Factories and large solar setups |

Composite materials are strong and resist rust. They are flexible and great for custom designs.

Aluminum frames are light and affordable. They resist rust, making them good for homes and businesses.

Stainless steel frames are very strong and handle bad weather well. They are used in factories and big solar setups.

High tensile strength is important for frame materials. It helps frames handle strong winds and heavy loads.

The frame helps attach and stabilize the solar panel. It keeps the panel secure on roofs or ground mounts. Good frames stop movement from wind or vibrations, keeping panels steady.

Wind tunnel tests show special designs, like rounded edges, cut wind pressure by 80%. These designs make panels more stable. Strong attachment methods, like triple-rail systems, work well in stormy areas.

A strong frame not only keeps the panel stable but also helps it last longer. By reducing stress on parts, the frame ensures the panel works well over time.

Tip: Pick a frame material and design that fits your area's weather for better durability and performance.

The junction box is where all the electrical parts connect. It holds diodes and connectors that control how electricity moves from the solar cells. These parts help send energy smoothly to the inverter or battery.

Modern junction boxes are designed to reduce energy loss. High-quality connectors and wires improve power flow, making sure the panel produces as much energy as possible. Below are some features that boost efficiency:

| Feature | Description |

|---|---|

| Enhanced Thermal Management | Special materials release heat, stopping overheating and keeping energy steady. |

| High-Quality Sealing | Blocks water and dust, keeping connections safe and efficient. |

| Optimized Electrical Performance | Top-notch connectors and wires lower resistance, improving energy transfer to the grid. |

These features make the system more reliable and help it work better over time.

The junction box protects the solar panel’s parts from bad weather. Its weatherproof design keeps it working well, even in tough climates.

Manufacturers test junction boxes to ensure they can handle harsh conditions. Common tests include:

Accelerated Stress Tests: Mimic real-life weather like sunlight, moisture, and temperature changes.

Real-Time Testing (RTT): Checks how the box performs over time in actual weather.

RILEM Durability Test: Combines lab weathering with mechanical stress to test seal strength.

| Testing Method | Description |

|---|---|

| Accelerated Stress Tests | Mimics sunlight, moisture, and heat cycles to test durability. |

| Real-Time Testing (RTT) | Observes long-term performance in real-world weather. |

| RILEM Durability Test | Tests seal strength with weather and mechanical stress combined. |

These tests prove that junction boxes can handle heat, humidity, and other challenges, helping the panel last longer.

The junction box is key to keeping the solar panel system safe and reliable. It controls electricity flow, prevents faults, and protects the system. A good junction box can handle high heat and current without losing performance.

Here are some facts about junction box reliability:

It manages current flow and ensures safety in solar systems.

A 25A junction box for a 182mm module has a 17.5% safety margin.

Tests show a 25A junction box works well even at 26A currents.

Outdoor tests confirm safety under high heat and humidity.

Studies show that a high-quality junction box improves overall system reliability. The chart below shows defect rates for different module types:

Choosing a solar panel with a strong junction box ensures steady energy and fewer problems. This part is crucial for the long-term success of your solar energy system.

Connectors and wiring help electricity move through a solar system. They link the solar cells to inverters or batteries, sending power where it’s needed. Good-quality connectors and wires reduce energy loss, so more power reaches your devices.

Bad connectors can cause problems like power loss or safety risks. For example:

Broken connectors may stop energy from flowing properly.

Cheap wires can overheat and damage the system.

Strong connectors, like 1500V-rated ones, handle high voltage safely.

Using reliable connectors and wiring makes your solar system safer and more efficient. It also helps the system last longer.

Picking the right connector is important for safety and efficiency. MC4 connectors are popular because they work well with most solar setups. They handle high currents and voltages without trouble.

When choosing connectors, think about these factors:

Current Rating: How much electricity the connector can handle.

Voltage Capacity: If it supports your system’s energy output.

Temperature Resistance: Protects against extreme heat or cold.

Ingress Protection (IP) Rating: Blocks dust and water.

Other connectors, like 2-to-1 Y branch connectors, make wiring simpler. They lower resistance, helping more power reach your devices. Their easy design also reduces mistakes during setup.

Good wiring keeps your solar system working well and reliably. High-quality wires prevent problems like overheating or energy loss. Studies show better wiring means fewer issues over time.

Use wires that match your system’s voltage and current needs. Proper insulation stops energy leaks and protects against water or sunlight damage. Regular checks can catch wear and tear early, avoiding bigger problems.

Investing in strong, durable wiring improves your system’s performance. It also lowers repair costs and keeps your energy flowing for years.

Solar panels need several key parts to turn sunlight into electricity. Each part, like solar cells, glass, and backsheets, is important. Solar cells make electricity, while films and frames protect and support the panel.

Knowing how these parts work helps with better setup and care. The table below shows factors that affect how well a solar panel works:

| Factor | How It Affects Efficiency |

|---|---|

| Sunlight Strength | More sunlight means more energy; less sunlight lowers output. |

| Wind Speed | Helps cool panels; cooler panels work better. |

| Outside Temperature | Hot weather lowers efficiency; cooler weather improves it. |

| Open-Circuit Voltage (Voc) | Shows the highest voltage the panel can make; helps predict voltage behavior. |

| Short-Circuit Current (Isc) | Shows the most current the panel can make; helps measure energy potential. |

| System Resistance | High resistance wastes energy; it slows current and lowers efficiency. |

| Maximum Power Point (MPP) | Shows the best conditions for making the most energy. |

By understanding these parts and factors, you can get the most from your solar panels and help the planet.

Solar panels have solar cells, glass covers, backsheets, frames, junction boxes, films, and connectors. Each part helps with making energy, protection, and lasting longer.

Protecting solar cells helps them work well and last longer. Glass and backsheets keep water, dust, and sunlight damage away, keeping energy steady.

Most frames are made of aluminum. It is light, strong, and doesn’t rust, making it good for all weather.

The junction box connects wires and controls electricity flow. It also keeps parts safe from water and heat, making the system more reliable.

The glass cover keeps solar cells safe from damage. It lets sunlight through and reduces glare, helping the panel make more energy.

The backsheet blocks water, sunlight, and damage. It also insulates the panel, keeping the inside parts safe and working longer.

Aluminum is light, doesn’t rust, and is affordable. These features make it great for strong and easy-to-install frames.

Solar cells are the most important part. They turn sunlight into electricity, making clean energy for homes and businesses.