Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

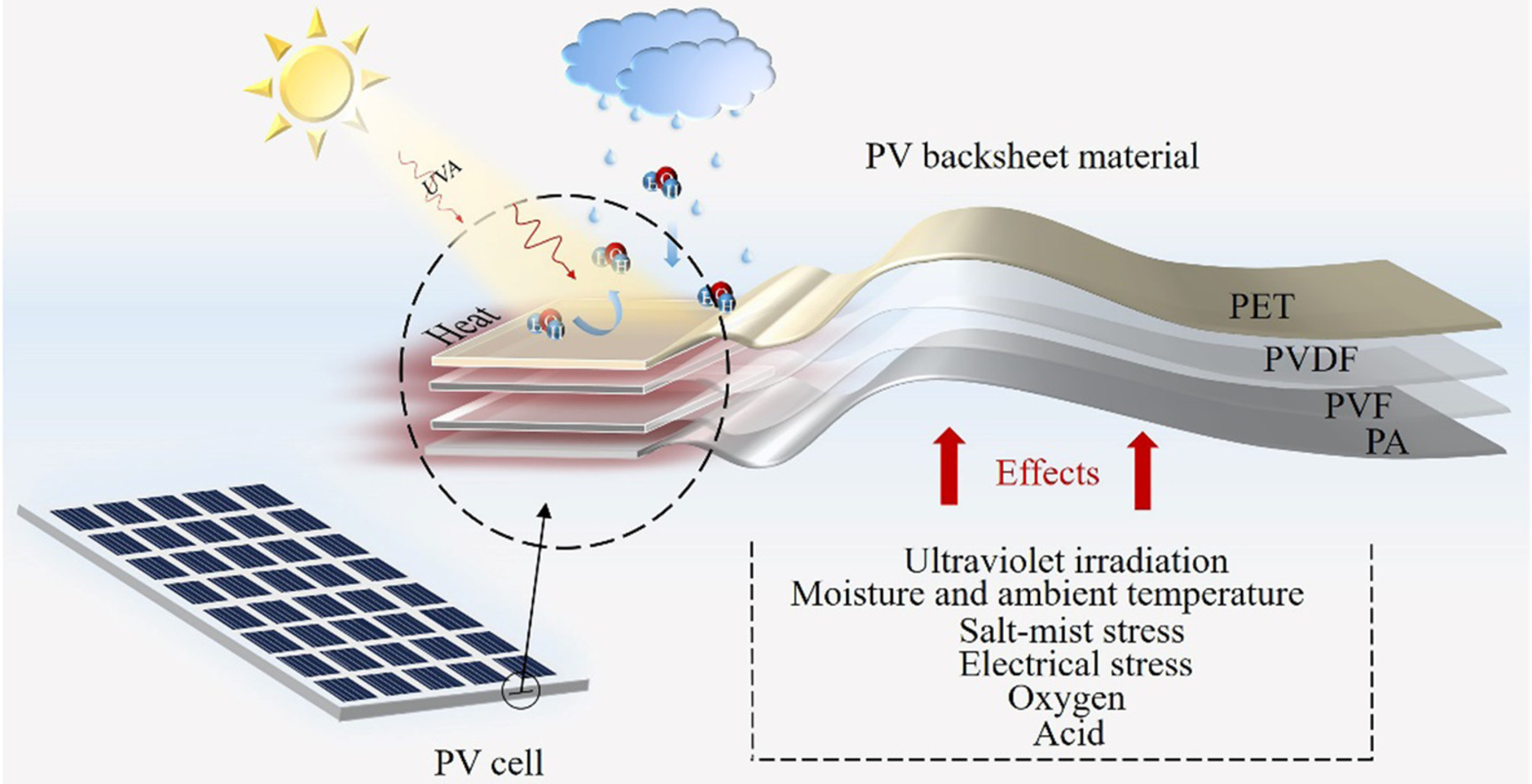

You want your solar modules to work well and last long. But things like water, UV rays, and hard cleaning can cause problems. Many owners worry about backsheet problems like cracking, turning yellow, and peeling. These problems can lower how well the modules work and make them less safe. Silicone is a new solution. If you use a backsheet silicone coating, you get better protection and easier cleaning. Recent studies show:

Between 9% and 16% of PV modules have backsheet problems.

Silicone-coated panels get back up to 97% of their power after cleaning, but uncoated panels only get up to 83%.

With silicone, you get stronger protection and easier care. This helps your solar panels last longer.

Backsheet silicone coating keeps water, UV rays, and dirt away from solar panels. This helps panels last longer and work better.

Silicone-coated panels can get back up to 97% of their power after cleaning. Uncoated panels only get back about 83%.

Silicone is hydrophobic, so less dirt sticks to the panels. This means you do not need to clean them as often. It saves time and money.

Silicone coatings are strong against heat and chemicals. This helps panels work well in all kinds of weather.

Using silicone can save a lot of money over time. It makes solar panels last longer and need less fixing.

You might wonder what a backsheet silicone coating does. This layer goes on the back of each solar panel. It works like a shield. It keeps water, sunlight, and dirt away from the solar cells. Using this coating adds a strong barrier. This helps your panels last longer and work better.

Silicone is a great choice for this job. Here are some reasons why:

It can handle heat up to 300°C, so panels stay safe on hot days.

It sticks well to many surfaces, so the coating stays put.

It stretches and is strong, so it does not crack or peel.

It bonds well with metals and plastics, so it works for many panel types.

Some products, like DOWSIL™ PV-9001, are used for this. These coatings help solar modules avoid damage and keep their power high.

Let’s see how silicone compares to other materials for backsheets:

| Material | Environmental Impact | Benefits |

|---|---|---|

| Silicone | Needs a lot of energy to make, does not break down in nature | Helps panels absorb more energy, protects from damage, makes panels last longer |

| Polyethylene Terephthalate (PET) | Has its own effect on the environment | Very clear and strong, lets sunlight reach the solar cells |

| Ethylene Tetrafluoroethylene (ETFE) | Light, stable, and stands up to weather | Very clear, helps panels work better and last longer |

| Epoxy | Stops water, chemicals, and UV light from getting in | Sticks very well, is strong, good for tough places |

Putting on a backsheet silicone coating takes care. Makers use liquid silicone and spread it over the backsheet. They cure it at room temperature or with heat. This makes the coating stick tight to the surface. The layer is smooth and strong. It covers the whole backsheet.

Silicone is picked because it makes a tough and bendy shield. It does not break down from sun, rain, or chemicals. Your solar panels get better protection. You do not have to worry about cracks or peeling. The coating also helps panels stay clean. This means you spend less time and money cleaning them.

You want your photovoltaic modules to last a long time. Water can get inside and cause big problems. If water gets in, it can rust parts and make panels work worse. Silicone gives strong protection from water. It acts like a shield and keeps water out.

Tests show silicone edge sealants make modules last twice as long before water causes trouble.

Regular modules let water in after 100 hours of hard testing. They get soaked by 500 hours.

Modules with silicone sealants stay dry for up to 400 hours. They do not get fully wet until 800 hours.

These modules keep making more power for over 1,000 hours of tough tests.

The fill factor stays steady, so you get better results.

Sunlight can also damage photovoltaic modules. UV rays break down materials and cause yellow spots or cracks. Silicone blocks UV rays and keeps layers safe. It helps stop delamination, so layers do not split apart. This keeps your solar panels working well for longer.

Tip: Using silicone helps protect your solar panels from water and sunlight. You get more years of good energy.

Here is a table that shows the main problems silicone helps stop:

| Failure Mode | Description |

|---|---|

| Moisture Ingress | Water gets inside and causes rust and damage. |

| Delamination | Layers split, letting water in and lowering how well panels work. |

| Environmental Degradation | Sun, rain, and pollution break down parts and make modules last less time. |

Heat can be bad for photovoltaic modules. You need materials that can handle hot and cold weather. Silicone gives strong protection from heat and cold. It does not break down when the weather changes. The bonds in silicone stay strong, so your modules keep working.

Here is a table that shows how silicone handles temperature:

| Temperature Resistance Type | Measured Range |

|---|---|

| High-temperature resistance | -40°C to 200°C for a long time, up to 250°C for a short time |

| Enhanced high-temperature resistance | 300°C–400°C with special additives |

| Low-temperature resistance | -60°C |

| Ultra-low-temperature resistance | -100°C |

| Thermal stability characteristics | Strong Si-O bonds resist breaking down and rusting |

You also need protection from chemicals. Pollution and cleaning products can hurt photovoltaic modules. Silicone resists stains, water, and chemicals. It gives a surface that does not let mold or mildew grow. This keeps your modules clean and safe.

Here is a table that shows how silicone protects against chemicals:

| Property | Description |

|---|---|

| Waterproof & Chemical Resistant | Stops stains, pollution, and water from causing harm |

| Mold & Mildew Resistant | Blocks germs and helps modules last longer |

Silicone coatings protect against pollution in the air.

You can use cleaning products without hurting the modules.

The surface stays strong and does not break down.

You get better results and longer life for your solar modules. Silicone helps keep solar panels working well, even in tough places. You spend less time worrying about damage and more time using clean energy.

You want your solar panels to stay clean. Dirt and dust can block sunlight. This makes your panels work less well. Silicone helps stop this problem. The silicone surface acts like a shield. Dust does not stick to it. Water slides off the silicone. It carries dirt away and keeps panels clean.

Silicone has special features that help a lot. The coating is superhydrophobic. Water forms beads and rolls off fast. You see less dirt and dust on your panels. Silicone’s self-cleaning comes from low surface energy. Tiny structures in the coating help water pick up dirt. Water moves the dirt away.

Here is a table that shows how silicone helps cleaning:

| Property | Description |

|---|---|

| Superhydrophobicity | Water beads up, so dust does not stick. |

| Self-Cleaning Capability | Water rolls off and takes dirt away. |

| Performance Comparison | Coated panels clean themselves better than plain glass. |

| Micro- and Nano-Structures | Tiny shapes help remove dirt and dust. |

Your solar panels stay cleaner with less work. Silicone coating helps your panels work better. You do not need to worry about dirt blocking sunlight.

Tip: Silicone coating means you clean less and get more power.

You want to save time and money on cleaning. Silicone makes taking care of panels easier. The hydrophobic coating stops water and stains from sticking. You do not need to clean your panels as much. The surface stays smooth and clear. You use less water and fewer cleaning products.

Here are ways silicone helps with maintenance:

You spend less money on cleaning supplies.

You use less water for cleaning.

You pay less for maintenance.

Silicone coating gives you self-cleaning power. Rain and water help remove dust and dirt. You do not need special tools or strong chemicals. The coating protects your panels and keeps them clean. Your solar panels work better and last longer.

Here is a table that shows more benefits of silicone:

| Property | Description |

|---|---|

| Hydrophobic Coating | Makes panels self-clean and cool, great for solar. |

| Application Methods | You can put the coating on in different ways to boost energy and help the planet. |

You get more value from your solar panels. Silicone coating helps keep panels clean and working well. You see better efficiency and lower costs. You enjoy clean energy with less work.

Image Source: unsplash

You want your solar panel to work well for a long time. Silicone helps make this happen. When you put silicone on the backsheet, it protects the panel from water, heat, and sunlight. This stops cracks and peeling. Your panel stays safe from harm. Silicone also helps your panel last longer. The coating does not wear out fast. You see less yellowing and fewer issues as years go by.

Silicone keeps your panel working well. Dirt and water do not stick to the surface. More sunlight gets to your panel. You get more power from your solar system. Silicone also helps your panel handle hot and cold weather. The coating works in all seasons. Your panel keeps making power even when the weather changes. You get steady energy all year.

Tests in the field show that silicone coatings help panels last longer. There is less rust and fewer leaks. The insulation stays strong. Your panel passes safety checks after bad weather. Here is a table that shows how silicone helps panels in real life:

| Description | Findings |

|---|---|

| Application of silicone sealant | Restores insulation resistance and keeps performance high |

| Electrical measurement after repair | Shows insulation resistance above safe operation levels |

| Damp heat treatment results | Panel keeps high insulation and passes wet leakage test |

| Repair method | Fills cracks, restores insulation, and adds a protective layer |

You save money when you use silicone on your solar panel. The coating makes your panel last longer. You do not need to buy new panels often. You spend less on fixing them. Silicone helps your panel work better for more years. You get more power from your solar system. You pay less for cleaning because dirt does not stick. Rain helps wash your panel. You use less water and fewer cleaning products.

Silicone helps your panel last longer. Your panel does not wear out fast. You get more years of good power. The coating also helps your panel work in hot and cold places. Your panel keeps working when the weather changes. You get more value from your solar panels.

Tip: Silicone coating helps you save money and get more power from your solar panel. You enjoy clean energy and lower costs.

You get strong protection and easy cleaning with backsheet silicone coating. This technology stops water from staying on your solar modules. It reflects most UV rays and stays bendy in hot or cold weather. You see fewer cracks and leaks because the layer keeps water out. The coating can last up to 25 years if you take care of it.

This technology dries water fast instead of soaking it up.

It stretches and shrinks when the weather changes, so your modules stay safe.

You spend less time fixing things because the coating stops damage.

| Year | Projected Adoption of Technology (%) |

|---|---|

| 2025 | 35 |

| 2027 | 50 |

| 2030 | 70 |

You keep your solar panels safe and help them work better with this technology. You can ask a solar expert to see if this technology is right for you.

The coating keeps dirt and water off your panels. Clean panels let in more sunlight. This means your solar system works better. You get more energy over time. Your panels make more power because they stay clean.

Yes, you can use silicone coating on almost all photovoltaic technology. It works with many kinds of solar panels. This helps protect your panels. Your energy system stays strong for a long time.

You do not need to clean your panels as much. The coating makes water roll off and take dirt away. You save time and use less water. This helps your panels make more energy.

Yes, silicone coating helps your panels keep making good energy for years. The coating protects against bad weather and damage. You get steady energy and do not need many repairs.

How PV Module Backsheets Impact Cleaning Requirements and System Longevity

What is MBB? Defining Multi-Busbar Technology in Half-Cut Solar Panel Manufacturing

Shingled Technology vs. Half-Cut Cells: Which Solar Panel Design Delivers Superior Performance?

SMBB Technology in Half-Cut Solar Cells: How Smart Multi-Busbar Design Improves Power Output

Amorphous Silicon PV Cells: Applications, Advantages, and Limitations of This Thin-Film Technology

From Cell to Module: The Manufacturing Process and Material Considerations in PV Production