Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

High temperatures make solar panels work less well, especially in hot places. High temperatures hurt pv module performance because of physical and electrical changes. Solar modules like PERC, TOPCon, IBC, and HJT lose efficiency when it gets hot. The temperature coefficient shows how much efficiency drops. For most modules, this number is between -0.24 and -0.34 %/°C. In hot climates, solar panels can get as hot as 65–70°C. This causes big drops in the energy they make.

Solar panel efficiency goes down when it gets hotter. This affects both how much power is made right away and over a year.

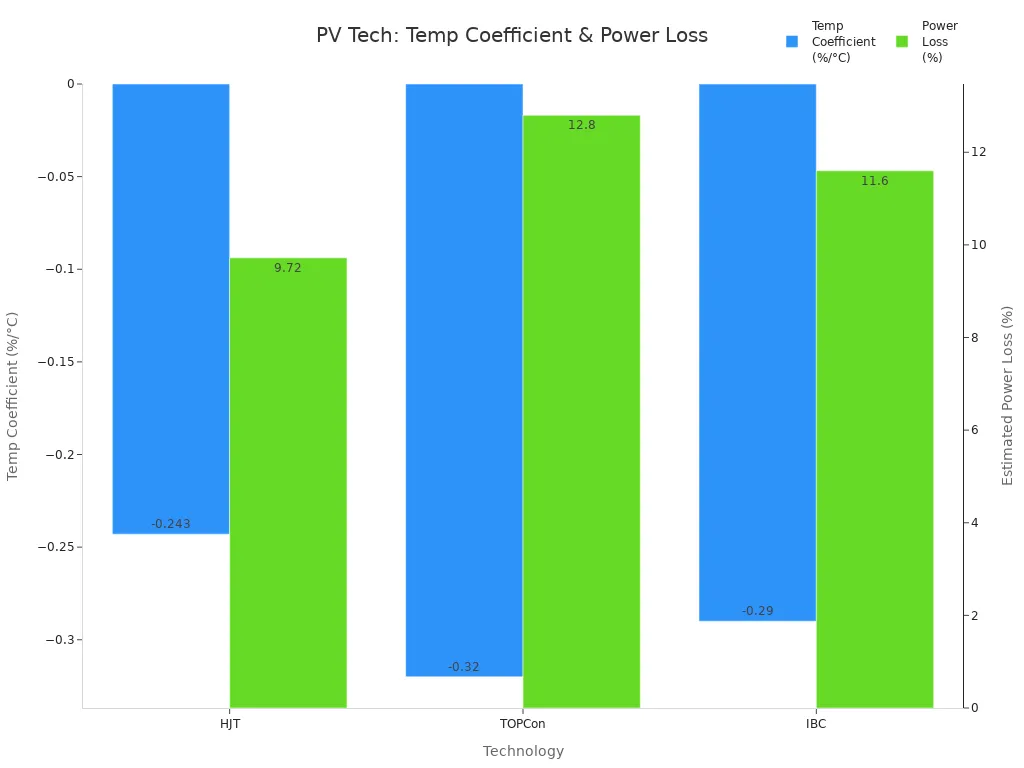

| Module Type | Temperature Coefficient (%/°C) | Estimated Power Loss at 40°C Rise |

|---|---|---|

| PERC | -0.34 | About 13.6% loss |

| TOPCon | -0.32 | About 12.8% loss |

| IBC | -0.29 | About 11.6% loss |

| HJT | -0.24 | About 9.6% loss |

Temperature effects on solar panel efficiency are a big worry for pv module designers. Studies show that temperature coefficients are different for each technology. These numbers do not get worse as time goes on. When temperature affects solar panel efficiency, it means less power and less money from solar energy systems.

High temperatures make solar panels work less well. This happens because heat changes things inside the modules. These changes cause the panels to make less power.

Different solar panel types lose power at different speeds. Some panels, like HJT and CIGS, do better in the heat. They keep more energy when it is hot outside.

Installing panels the right way helps them stay cool. Raising panels lets air move under them. Using cooling materials also helps panels work better.

The materials in solar panels matter a lot. Things like encapsulants and coatings help panels handle heat. These materials also help panels last longer in hot places.

Cooling systems and smart technology can help panels work better. They can make solar panels up to 15% more efficient. This makes solar energy more useful and cheaper in warm places.

Solar panels make electricity using the photovoltaic effect. Sunlight hits the solar cell and moves electrons. This movement creates electric current. The bandgap is the energy needed to free electrons. Different pv modules have different bandgaps. The bandgap changes how well sunlight turns into electricity.

When it gets hotter, the bandgap gets smaller. This means electrons need less energy to move. But more electrons can recombine before being collected. How well a module cools affects its best bandgap. If a module cannot cool fast, its efficiency drops more. For CIGSe solar cells, controlling the bandgap helps voltage and efficiency. This shows why keeping modules cool is important for pv performance.

Note: Heat changes how electrons act inside the module. This starts at the atomic level and affects efficiency.

Temperature changes the voltage and current from a solar module. When it gets hotter, the open-circuit voltage (VOC) goes down. This happens because more charge carriers are inside the cell. Electrons can move back more easily. For silicon solar panels, voltage drops about 2.2 millivolts per degree Celsius.

The short-circuit current (ISC) goes up a little with heat. Higher temperatures make it easier for electrons to move. So, a bit more current flows. But the voltage drop is much bigger than the current gain. This means the module’s power and efficiency go down as it gets hotter.

Hotter temperatures make the open-circuit voltage drop.

The short-circuit current rises a little because electrons move easier.

The voltage drop is bigger than the current gain, so efficiency falls.

Changes in resistance inside the module also change the output.

Tests show these things happen. When a panel heats up, voltage drops, current rises a bit, and total output falls. That’s why temperature is a big worry for solar system designers.

Heat makes electrons and holes recombine more inside the cell. If they recombine before reaching the contacts, the module loses electricity. Hotter temperatures make this recombination happen more often. This lowers the current and makes the panel less efficient.

The module’s temperature changes how many electrons recombine.

More defects in the material mean more recombination spots.

Heat raises resistance inside the module, making current flow harder.

More recombination and resistance lower efficiency and output.

Studies show that higher temperatures raise the cell’s resistance. This makes it harder for electricity to move through the module. So, performance drops even more. Both recombination and resistance together mean hot weather can cause big power losses.

In summary, temperature affects pv modules by changing bandgap, voltage, current, recombination, and resistance. All these things work together to lower efficiency as it gets hotter.

Solar panels get their ratings from Standard Test Conditions, called STC. STC uses perfect lab settings. The cell temperature is set at 25°C. Sunlight is very strong at 1000 W/m². But real life is not like the lab. Outside, solar panels get hotter and sunlight is weaker. Wind and air mass also change how well panels work.

| Parameter | Standard Test Conditions (STC) | Real-World Operating Conditions (NOCT) |

|---|---|---|

| Irradiance | 1000 W/m² (ideal sunlight intensity) | 800 W/m² (lower, more typical sunlight) |

| Temperature | Cell temperature at 25°C (77°F) | Ambient temperature at 20°C (68°F); cell temp ~45°C |

| Air Mass | 1.5 (standardized atmospheric path length) | Not specified, varies with location |

| Wind Speed | Not considered | 1 m/s (affects cooling and temperature) |

The table shows that STC is like a perfect world. In real life, solar modules often reach about 45°C. They also get less sunlight than in the lab. These changes make solar panels less efficient. In real life, panels usually give only 70–80% of their STC rating. Engineers use these numbers to guess how much power a system will make outside the lab.

Other things also lower how much power you get. The next table lists common losses in real solar systems:

| Loss Factor | Typical Loss Range / Impact |

|---|---|

| Temperature Effects | Efficiency decreases as module temperature rises (e.g., 5-10% derate) |

| Wiring and Conduction | Energy lost in cables and connections (1-3%) |

| Inverter Efficiency | Conversion losses from DC to AC (95-98% efficiency) |

| Soiling and Shading | Output reduction due to dust, dirt, snow, shading (2-5%) |

| Module Degradation | Annual efficiency loss around 0.5% per year |

Solar panels work better in the lab than outside. The Performance Ratio, or PR, compares real output to perfect output. PR numbers go from 66% to 88%. This means many things, like heat, wires, and age, all lower solar panel efficiency.

The temperature coefficient tells us how much a solar module’s power drops when it gets hotter than 25°C. You can find this number on datasheets. It is shown as a percent for each degree Celsius. Engineers use the temperature coefficient to figure out how much power is lost when the panel heats up.

The temperature coefficient affects important things:

Open-circuit voltage (VOC)

Short-circuit current (ISC)

Maximum power point (Pmpp)

For example, if a module has a temperature coefficient of -0.3%/°C, it loses 0.3% of its power for every degree above 25°C. Technicians check this by watching how voltage, current, or power changes as the panel gets hotter. The temperature coefficient helps people design systems and avoid problems from high voltages when it is cold.

Solar panel efficiency depends on the temperature coefficient. Lower numbers mean less power loss in hot weather. Some modules, like HJT, have better temperature coefficients. These are good for places that get very hot.

Solar modules lose power as they get hotter. Engineers use math to guess how much is lost. One formula for cell temperature looks like this:

Tcell = Tamb + (1 / U) * (Alpha * Ginc * (1 - Effic))

Tcell: cell temperature

Tamb: ambient temperature

U: heat loss factor (W/m²·K)

Alpha: absorption coefficient (usually 0.9)

Ginc: incoming sunlight (irradiance)

Effic: solar panel efficiency

If the air is 35°C, sunlight is 800 W/m², and the panel is 20% efficient, the cell can get hotter than 55°C. Higher cell temperatures mean more power is lost. If the temperature coefficient is -0.3%/°C, a 30°C rise above 25°C means a 9% drop in power.

Scientists have studied rooftop solar for years. They found that heat loss is a big part of total losses. These are called array capture losses. Over time, panels also lose about 0.5% efficiency each year. Dust, shade, and wiring losses make things worse.

Tip: Always check the temperature coefficient and use real data to predict losses.

Solar panels lose power in hot weather. By measuring these losses, designers can pick the best panels and ways to install them for more power.

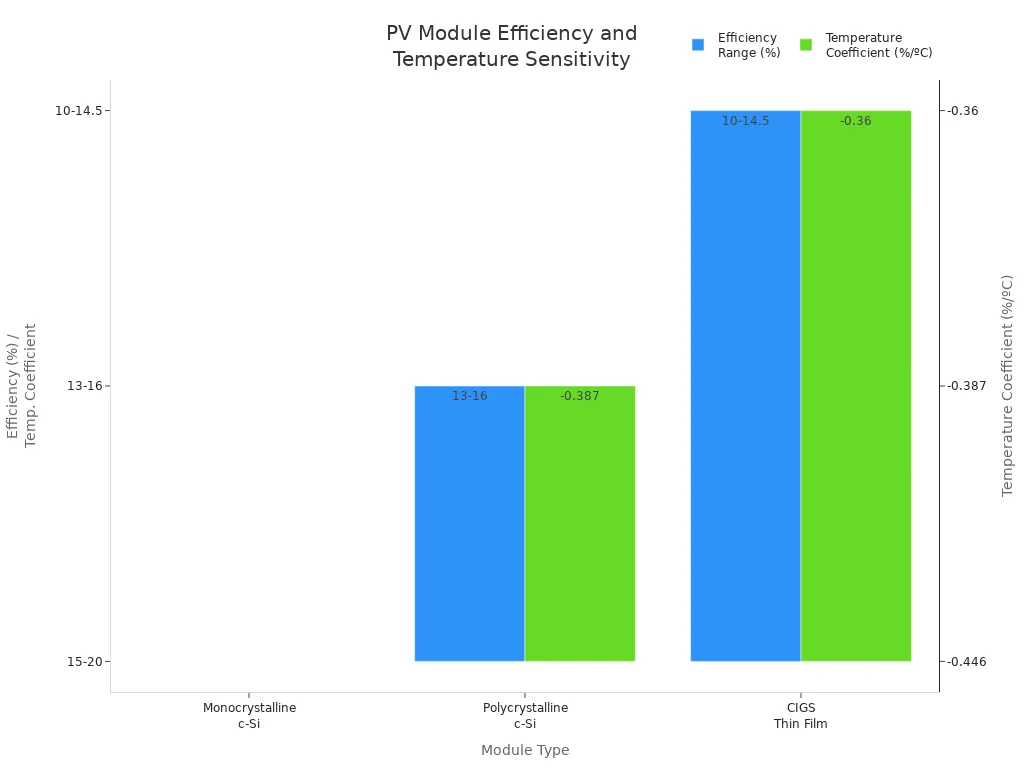

Solar panels use different materials to make electricity from sunlight. Crystalline silicon modules work well in normal conditions. Monocrystalline silicon modules can reach up to 26.7% efficiency. Polycrystalline modules can reach 24.4% efficiency. Thin film modules, like CIGS, have lower efficiency. But they do better in hot places. CIGS modules lose less efficiency when it gets hot. Their temperature coefficient is only -0.36%/°C. Crystalline silicon modules have higher temperature coefficients. This means they lose more power when it is hot. Thin film modules also work better when there is less light or some shade.

| Module Type | Efficiency Range (%) | Temperature Coefficient (%/ºC) | Temperature Sensitivity and Efficiency Losses Summary |

|---|---|---|---|

| Monocrystalline c-Si | 15 - 20 | -0.446 | High efficiency but loses more power as it gets hotter |

| Polycrystalline c-Si | 13 - 16 | -0.387 | Medium efficiency and medium sensitivity to heat |

| CIGS Thin Film | 10 - 14.5 (typical) | -0.36 | Lower efficiency but less affected by heat, works better in hot and low light |

Thin film modules keep working well in hot and changing light. Crystalline silicon modules have higher peak efficiency but lose more power when it gets hot.

Solar technology keeps getting better. HJT modules reach up to 26.56% efficiency in labs. They keep good performance even when it is hot. Their temperature coefficient is about -0.25%/°C. So, they lose less power when it gets hot. TOPCon modules have high efficiency and are not too expensive. Their temperature coefficient is near -0.32%/°C. IBC modules use a back-contact design. This helps reduce shading and gives 22–24% efficiency. Their temperature coefficient is about -0.29%/°C. PERC modules are used a lot but lose more efficiency in heat.

| Technology | Temperature Coefficient (%/°C) | Estimated Power Loss (25°C to 65°C) | Efficiency Characteristics and Application Context |

|---|---|---|---|

| HJT | About -0.243% | About 9.72% | Best temperature stability; efficiency over 24%; low degradation; good for hot, sunny places and building use. |

| TOPCon | Around -0.32% | About 12.8% | Medium temperature coefficient; efficiency limit about 28.7%; good price; works well in warm places. |

| IBC | Around -0.29% | About 11.6% | High efficiency (22-24%); looks nice; less shading; good for fancy buildings. |

| PERC | Higher temperature sensitivity | Higher power loss than others | Used a lot but loses more power in heat; efficiency drops more at high temperatures. |

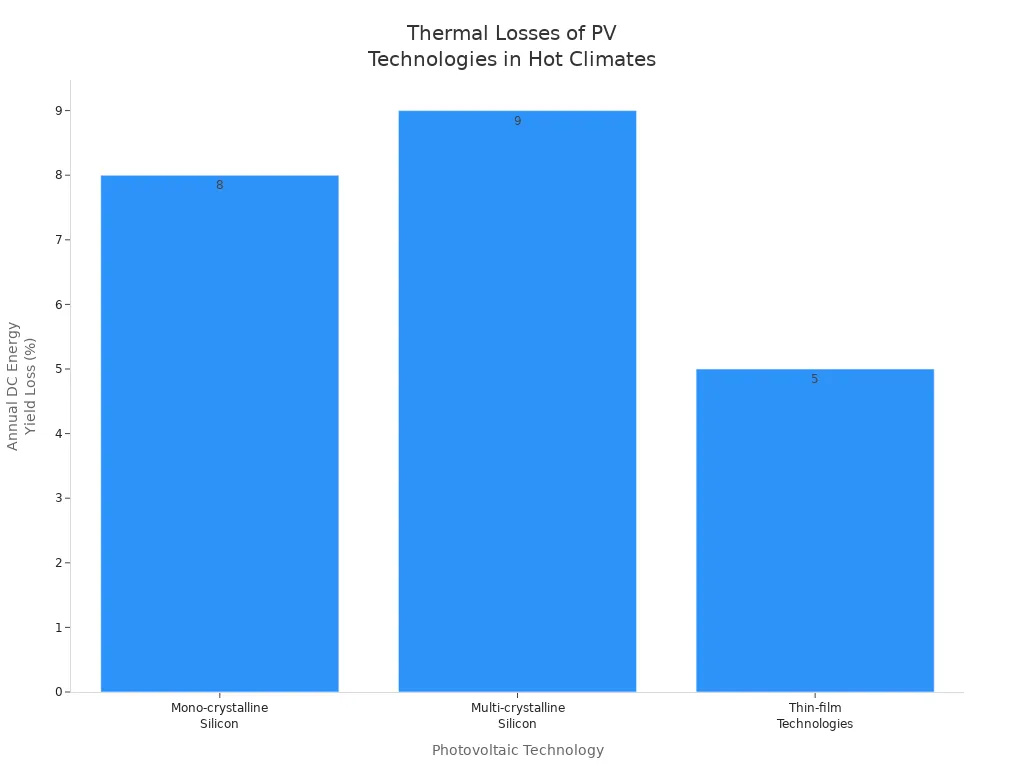

Solar modules act differently outside the lab. In hot places, crystalline silicon modules lose 8–9% of their yearly energy because of heat. Thin film modules lose only about 5%. CIGS modules keep a better performance ratio between 10–50°C. Things like dust, humidity, and wind also change how well pv modules work. Dust and humidity can cause up to 30% power loss. Cooling methods, like hybrid PV-thermal systems, help panels work better in hot places.

| Photovoltaic Technology | Thermal Losses in Hot Climates | Performance Ratio / Effects in Hot Climates |

|---|---|---|

| Mono-crystalline Silicon (mono-c-Si) | 8% yearly energy loss | Lower performance ratio than CIGS; loses more power when hot |

| Multi-crystalline Silicon (multi-c-Si) | 9% yearly energy loss | Similar losses as mono-c-Si; heat lowers performance |

| Thin-film Technologies | 5% yearly energy loss | Better at handling heat; loses less power |

| Amorphous Silicon (a-Si) | N/A | Works better in warm months because of thermal annealing |

| Copper Indium Gallium Selenide (CIGS) | N/A | Higher performance ratio than crystalline silicon PVs between 10–50°C |

PV module performance depends on the type, weather, and how it is set up. Picking the right solar module helps get more energy and save money, especially in hot places.

Image Source: pexels

Encapsulation materials keep solar cells safe from heat and water. They also protect against bumps and pressure. The type of encapsulant changes how well a module handles heat. It also affects how long the module lasts.

EVA grows more than metals and silicon when it gets hot. This makes stress inside the module during heating and cooling.

Stress can cause cracks or broken parts inside the module.

Picking the right encapsulant lowers the chance of damage. It helps the module stay strong.

How much encapsulants stretch and shrink affects how layers stick together. This changes how tough the module is.

Adding things like SiC, BN, or ZnO to EVA helps heat move out faster. For example, mixing 30% SiC made thermal efficiency reach 70.02%. Electrical efficiency went up to 16.94% because the cell stayed cooler.

Better heat flow from these additives can make power go up by more than 7%.

Tip: Using good encapsulation materials and special additives helps pv modules stay cool and work better in hot places.

How the module’s wires and paths are built helps control heat and electricity. Scientists found that using graphite and aluminum films in the backsheet cools crystalline silicon modules. This cooling makes voltage and power conversion better. Good heat paths in the frame and backsheet move heat away from the cells. Adding phase change materials with metals cools modules even more. Temperatures can drop by up to 21.9 K. Electrical efficiency can go up by 9%. Smart design of conductive pathways lowers losses from heat and boosts pv system output.

High heat makes modules age and break down faster. Over time, heat, sunlight, and water cause rust, cracks, and weaker materials. Light-Induced Degradation (LID) and Potential-Induced Degradation (PID) are common problems. LID happens when sunlight changes chemicals in silicon cells. This causes early power loss. PID comes from high voltage differences. It makes leakage currents and big power drops. The encapsulation layer can turn yellow, crack, or stop sticking. This lets less light through. Backsheets can break down from heat and water. This lets moisture in and causes leaks. Tiny cracks and metal lines coming loose also lower efficiency. Using strong materials and good designs, like glass-glass modules and UV-resistant backsheets, slows these problems down.

| Mechanism | Description and Cause | Effect on PV Modules and Degradation Rate |

|---|---|---|

| Potential-Induced Degradation (PID) | High voltage moves ions and makes paths. Sodium ions in glass help this happen. | Up to 30% efficiency loss; power loss ~2.02% per year. |

| Light-Induced Degradation (LID) | Sunlight speeds up oxidation in silicon cells. | Up to 10% efficiency loss, mostly in the first year. |

| Encapsulation Aging | UV and heat make yellowing, cracks, and loss of stickiness. | Less light gets in; efficiency drops over time. |

| Backsheet Degradation | Heat and water cause breakdown and peeling. | More moisture and rust; early failure. |

| Cell Degradation | Tiny cracks and metal lines come loose from heat. | Power loss and lower efficiency. |

| Hotspot Formation | Cell problems or dust make some spots too hot. | More damage and efficiency loss. |

| Mechanical Stress | Stretching and shrinking cause cracks. | Solder joints and cells break. |

| Soiling/Dust Accumulation | Dust blocks light and makes hotspots. | Power loss of 1.27% per g/m² of dust. |

Note: High heat makes all these problems worse by speeding up chemical changes and stressing materials. Picking good materials and smart designs helps modules last longer in tough places.

Ambient temperature and sunlight both affect how solar panels work. When it gets hotter than 25°C, panels lose about 0.3% to 0.5% efficiency for each degree. In very hot places, panels can get as hot as 60°C. This can make them lose 10–15% of their power compared to what they are rated for. Cold places with strong sunlight can help panels work better, giving a 5–7% boost in efficiency. More sunlight means more total energy, even if some is lost from heat. Panels usually run 20–40°C hotter than the air, so local weather is important. Wind helps cool panels down. Just a little wind, like 1 m/s, can lower panel temperature by 5–11°C. The table below shows how these things change how well solar panels work:

| Factor/Condition | Effect on PV Efficiency/Output | Explanation/Example |

|---|---|---|

| Temperature increase (>25°C) | Efficiency loss of 0.3% to 0.5% per 1°C rise | Panel temperature can reach 60°C causing 10-15% power output decrease compared to rated efficiency |

| Very cold conditions (0°C) | Efficiency gain of 5-7% above rated output | Cold climates with high irradiance improve efficiency |

| High solar irradiance | Increases total energy output despite temperature losses | Hot sunny days yield more energy than cool cloudy days |

| Wind speed | Cooling effect reduces panel temperature by 5-11°C at 1 m/s | Cooling improves efficiency |

In tropical places, high humidity and heat can make efficiency drop by up to 28.7%. Checking and cleaning panels often helps keep them working well.

Airflow is very important for keeping panels cool. When air moves over both sides of a panel, it takes away heat faster. If panels are raised above the roof, air can flow underneath and cool them more. The color of the roof also matters. Dark roofs under panels can sometimes stay cooler than if there were no panels. Light or shiny roofs might make the air around the panels warmer. Cool roofs with panels can make the area cooler at night, but the roof itself might stay warmer because panels block heat from leaving. How panels are put up also matters. Roof-mounted panels are usually 5–10°C hotter than ground-mounted ones because they get less air moving around them.

Tip: Raising panels and letting air flow under them helps keep them cool and work better.

The time of year and where you live change how well panels work. In hot places, panels lose about 0.4% efficiency for every degree above 25°C. Where you are on Earth changes the sun’s angle and how long the sun shines, so places farther from the equator have bigger changes through the year. Tropical areas have extra problems from clouds and humidity, which block sunlight and can make water build up on panels. Dust in deserts can also lower efficiency if panels are not cleaned often. Cooler places often get better efficiency, even if they have less sunlight. Every place needs its own plan for design and cleaning to get the most energy all year.

Hot places need good cooling and cleaning.

Cooler places lose less efficiency from heat.

Tropical areas must deal with humidity and clouds.

Desert places need to control dust.

How well solar panels work depends on many things that change their temperature, so picking the right setup for each place is very important.

Annual yield means how much electricity a solar system makes in one year. Hot weather makes panels less efficient, so they make less energy. If efficiency drops by 10–15% in hot places, the total energy goes down too. This drop changes the levelized cost of electricity (LCOE). LCOE is the average price to make one unit of electricity over the system’s life. When panels are less efficient, each kilowatt-hour costs more money. In hot areas, solar systems often have higher LCOE. This is because panels work worse and need more cleaning or cooling.

How you design the system affects how much money you save. Engineers use special materials and cooling tricks to keep panels cooler. For example, phase change materials (PCMs) can cool panels by up to 34°C. Cooler panels work better, so you get your money back faster. Using water with PCMs can make panels up to 13.7% more efficient. Dust can lower efficiency by almost 12%. Cleaning dust off keeps energy high and makes the system worth more. The table below shows how design choices change performance and cost:

| System Design Aspect | Impact on Performance | Economic Impact |

|---|---|---|

| Integration of PCMs | Makes panels cooler, boosts efficiency | Faster payback, better investment |

| Cooling Strategies (Water + PCM) | Higher efficiency, better heat control | More energy, higher profits |

| Dust Mitigation | Keeps panels working well | Keeps output high, adds value |

| PCM Type Selection | Best cooling for the system | Changes cost and design |

Some solar systems can reach 37% efficiency but cost more and need strong sunlight. Fixed-tilt systems are cheaper and work in many places. Engineers pick the best system for the sunlight and budget in each area.

Solar panels lose efficiency over time from heat, dust, and getting old. Most panels lose about 0.5% efficiency every year. In hot places, this can happen faster and cost more money later. When panels degrade, they make less energy and save less money. Owners should plan for these losses when thinking about payback and savings. Using strong materials and smart designs helps slow down damage and protect your money.

Good design and regular care help solar panels last longer and save money, even in hard climates.

Engineers use different ways to keep solar panels cool. They pick passive cooling, like letting air move around the panels. Heat sinks help take away extra heat without using more energy. Raising panels and leaving space under them lets air flow and cool them down. Changing how panels face the sun and tilting them helps stop heat from building up. It also helps panels get more sunlight. Some setups use phase change materials, such as paraffin jelly, to soak up heat and let it out later. These methods help control temperature and keep panels working well.

Picking the right materials helps keep panels cooler. Shiny coatings and light-colored roofs do not soak up as much heat. Panels with high sub-bandgap reflectance bounce back sunlight that cannot be used. This keeps them cooler. Materials with high emissivity send heat away faster. These tricks help panels last longer and work better.

Cooling is very important for solar panels. Passive cooling, like phase change materials, can make panels give about 9% more power. Active cooling uses water or air to cool panels but costs more and is harder to set up. Hybrid systems mix thermoelectric coolers and phase change materials for even better results. Some hybrid coolers can lower panel temperature by over 40°C. They can also make panels work up to 15% better. These ideas help panels stay cool in hot places.

Smart coatings help panels soak up more light and keep dust off. Some coatings clean themselves and stop reflection. Dual-layer phase change materials help keep panel temperature steady by taking in and letting out heat. Real-time monitoring uses artificial intelligence to watch and change how panels work. These tools help panels keep making power even when the weather changes.

| Solution Type | Benefit | Example Impact |

|---|---|---|

| Hybrid Nano Coatings | Cut down reflection and stop dust | More photons used |

| AI Monitoring | Changes settings as weather changes | Gets more energy |

| PCM Layers | Take in and let out heat to keep panels cool | Less damage from heat |

Some solar panel types work better when it is hot. HJT modules lose less energy and make more power in tropical and dry places. CIGS cells keep working well even when it is very warm. CdTe modules can make up to 6% more energy than silicon ones in hot weather. Picking the best technology helps panels work better and last longer in hot places.

Scientists are finding new ways to help solar panels with heat. They use special materials to make panels stronger in hot weather. Some scientists put tiny MOFs into perovskite solar cells. These MOFs give the cells more flexible shapes and bigger surfaces. This helps stop damage from sunlight and heat. In CIGS solar cells, a very thin Al2O3 layer protects the cells. This layer is only 10 nanometers thick. It keeps water out and stops electrical problems. Because of this, the cells keep about 80% of their power after being in hot, wet places for a long time. Nanofluids and paraffin-based nanomaterials help cool the panels. They move heat away from the panels. Carbon-black nanofluids and phase change materials with nanoparticles keep the temperature steady. These new materials and nanotechnologies help solar panels last longer and work better when it is hot.

Smart coatings and artificial intelligence help solar panels handle heat. The table below shows how these tools help:

| Mechanism | Description | Effect on PV Efficiency under High Temperature |

|---|---|---|

| Hybrid Nano Coatings | Lower reflection, use more UV/IR light, and block dust | More light used, less power lost from dirt |

| Phase Change Materials (PCMs) | Take in and let out heat to keep panel temperature steady | Less damage from heat, longer panel life |

| AI-Driven Adaptive Systems | Use machine learning to change settings and follow the sun | More power made, even when it gets hot |

Smart coatings help panels take in more light and stay clean. PCMs store extra heat during the day and let it out when it cools down. This helps keep panels from getting too hot. AI systems watch the weather and change how panels work. This helps panels make more energy, even when it is very hot.

Hybrid and advanced systems use many ways to fight heat and work better. Hybrid solar systems mix photovoltaic panels with ground source heat pumps. They also use special parts for each climate. Engineers choose the right size for collectors, heat exchangers, and storage tanks. This helps balance heating and electricity needs. Phase change materials in these systems store heat and help cool the panels. This keeps panels from getting too hot. Control systems manage energy and lower the need for grid electricity. This is helpful in hot places. Hybrid photovoltaic-thermal (PVT) systems make both electricity and heat. These systems use cooling to keep panels working well, even at noon when it is hottest. Advanced insulation, like aerogels, and smart controls using machine learning, help these systems last longer and work better. Hybrid designs lower greenhouse gas emissions and make solar energy more reliable in hot places.

Solar panels do not work as well when it gets hot. Each type of panel reacts to heat in its own way. The temperature coefficient tells us how much power is lost when it is hot. People can make panels work better by picking good ways to install them and using the right materials.

To get the best results, it is smart to ask an expert for help before setting up a solar system. This helps make sure the panels work well no matter where you live.

The temperature coefficient tells us how much power a solar panel loses when it gets hotter than 25°C. If the coefficient is lower, the panel does not lose as much power in hot weather.

High temperatures make solar panels age faster. They can cause cracks and yellow spots. The materials break down more quickly. This makes the panels less efficient and shortens how long they last.

HJT and CIGS modules work best in hot places. They have lower temperature coefficients. This means they lose less power when it is hot. These panels keep their efficiency higher in warm areas.

Yes. Cooling systems like phase change materials or water cooling help keep panels cooler. These systems can make panels up to 15% more efficient in very hot weather.

Dust blocks sunlight and makes some spots hotter. This raises the panel’s temperature and causes more power loss. Cleaning the panels often helps keep them cooler and working better.