Views: 0 Author: Site Editor Publish Time: 2025-06-10 Origin: Site

Solar panel manufacturing is key to renewable energy, changing how we use sunlight. Today, solar power provides energy for over 4.7 million U.S. homes. In 2022, solar made up 15.9% of renewable electricity, up from 13.5% in 2021. California is leading, showing how solar can change energy worldwide.

Learning how solar panel manufacturing works helps you understand this clean energy. Each panel uses special materials and careful design to turn sunlight into energy. By knowing this process, you see how solar power supports a greener future.

Solar panels are important for clean energy, powering many homes and making lots of electricity.

Learning about materials like silicon and glass shows how they help make clean energy.

Making solar panels has many steps, from shaping silicon to putting panels together, to make them strong and work well.

Checking quality is very important, with tests making sure panels work in all kinds of weather.

New technology and machines are making solar panels better and cheaper, helping us use energy that’s good for the planet.

Solar panels need specific materials to turn sunlight into energy. Each material has a job to make panels work well and last long. Let’s look at the main and special materials used in these energy systems.

Solar panels start with basic materials. These are the key parts that help panels collect sunlight and make electricity.

Silicon: Silicon is the most important part of solar panels. It works as a semiconductor, soaking up sunlight to create electricity. Manufacturers cut silicon into thin pieces called wafers, which are the heart of solar cells. It’s popular because it’s common and works well.

Glass: The glass layer keeps solar cells safe from damage. It also lets sunlight pass through. Tempered glass is strong and can handle tough weather like hail or wind.

Aluminum: Aluminum frames hold the panels together. They are light but strong, making them easy to install and able to handle outdoor conditions.

EVA (Ethylene Vinyl Acetate): EVA is a clear material that wraps around solar cells. It protects them from water and stress while keeping them in place.

Backsheet: The backsheet is the bottom layer of the panel. It guards the inside parts from sunlight, water, and other damage, helping the panel last longer.

Besides the main materials, solar panels use special ones to work better and keep up with new technology. These materials help make panels more powerful.

Polysilicon: Polysilicon is a pure form of silicon used in solar cells. About 90% of it gets used in production, with factories making 122,000 to 128,000 tons each month. It’s key for high-quality solar wafers.

PERC Cells: PERC cells are advanced solar cells that absorb more light. Factories make 48 gigawatts (GW) of these cells monthly, using 70% of their capacity. They are very efficient and widely used.

N-Type Cells: N-type cells are a newer kind of solar cell. They produce 10-12 GW each month and last longer than older types.

Specialized Coatings: Special coatings on the glass reduce sunlight reflection. This helps more sunlight reach the cells, making the panels more efficient.

Advanced Modules: Top manufacturers use 82% of their capacity to make 46 GW of advanced solar modules yearly. These panels use the latest materials and designs to produce more energy.

By mixing basic and special materials, solar panels keep improving. Knowing what goes into them helps you understand how they support clean energy. You can check the key materials in solar panel manufacturing get more information.

Solar panels have important parts that work together to make energy. Each part has a job to keep the panel working well and lasting long. Here are the main parts:

Solar Cells: These are the most important part of the panel. They take in sunlight and turn it into direct current (DC) electricity. The two main types are Monocrystalline and Polycrystalline, which differ in how they are made and how well they work.

Glass Layer: This layer keeps the solar cells safe from damage. It also lets sunlight pass through. Tempered glass is strong and can handle bad weather.

Frame: The frame, usually made of aluminum, holds the panel together. It gives support and makes installing the panel easier.

Backsheet: This is the bottom layer of the panel. It protects the inside parts from water, sunlight, and other damage.

Inverter: This is not part of the panel but is very important. It changes the DC electricity from the solar cells into alternating current (AC) electricity for your home.

Each part of a solar panel helps it work well and last longer. For example, solar cells make energy, but they slowly lose efficiency over time—about 0.5% each year. After six years, a panel might still work at 93.75% of its original power.

The glass layer and frame keep the panel strong. If the panel isn’t supported well, it can break during storms. Checking your roof and support beams before installing panels is very important.

The backsheet and coatings protect the panel from weather and wear. Cleaning the panels can also help them work better. Dirt can lower energy production by up to 6.3%. Cleaning can boost energy output by over 12%, showing why maintenance matters.

By learning what each part does, you can see how solar panels are built to work efficiently and handle tough conditions.

Making solar panels involves many careful steps. These steps turn raw materials into panels that make energy from sunlight. Each step is important to make sure the panels work well and last long.

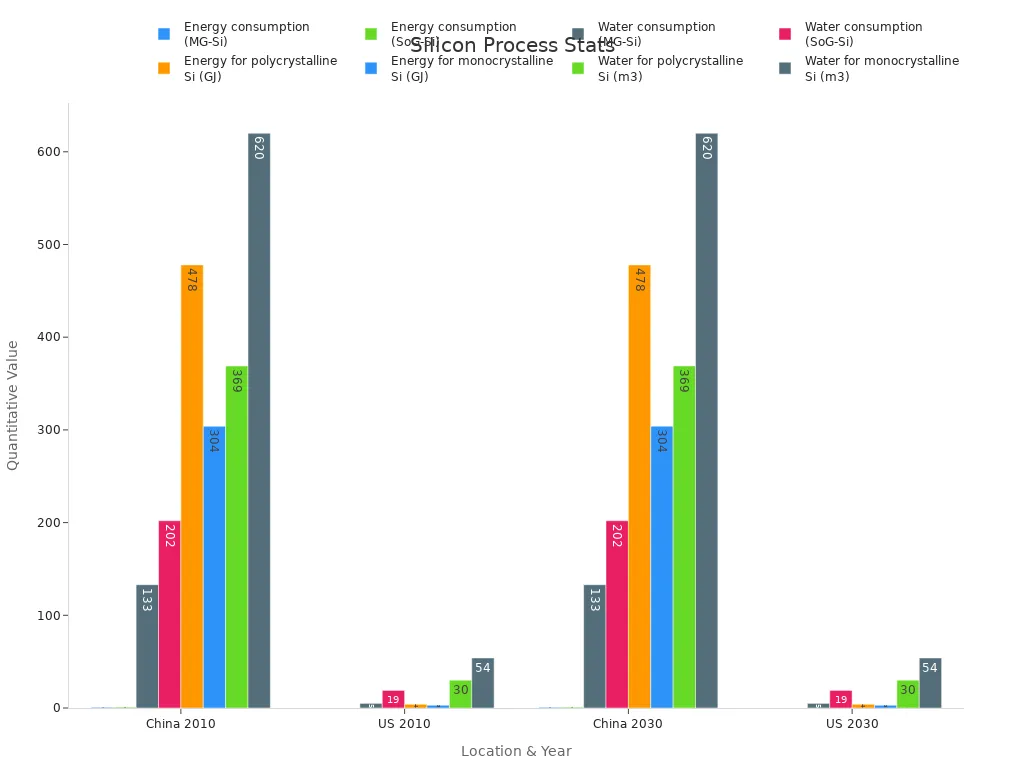

Silicon is the main material for making solar panels. It helps turn sunlight into electricity. First, silicon is cleaned to make it pure enough for solar cells. There are two types: metallurgical-grade silicon (MG-Si) and solar-grade silicon (SoG-Si). MG-Si is cleaned even more to meet strict solar standards.

This process uses a lot of energy and water. For example, in 2010, China used 0.8 million MJ of energy and 133 m³ of water to make MG-Si. The U.S. used much less—0.05 million MJ of energy and 5 m³ of water. By 2030, these numbers are expected to stay the same. Making SoG-Si needs even more resources. China used 0.9 million MJ of energy and 202 m³ of water per unit, while the U.S. used 0.06 million MJ of energy and 19 m³ of water.

| Category | China (2010) | US (2010) | China (2030) | US (2030) |

|---|---|---|---|---|

| Energy use (MG-Si) | 0.8 million MJ | 0.05 million MJ | 0.8 million MJ | 0.05 million MJ |

| Energy use (SoG-Si) | 0.9 million MJ | 0.06 million MJ | 0.9 million MJ | 0.06 million MJ |

| Water use (MG-Si) | 133 m³ | 5 m³ | 133 m³ | 5 m³ |

| Water use (SoG-Si) | 202 m³ | 19 m³ | 202 m³ | 19 m³ |

This step makes sure the silicon is good enough to turn sunlight into energy.

After silicon is cleaned, it is melted and shaped into ingots. These ingots are cut into thin wafers, which are the base for solar cells. The wafers must be the right thickness to work well.

Big improvements have been made in this step. For example:

Adani Solar will add 2 GW of ingot and wafer capacity by 2023. They plan to reach 10 GW by 2025.

CubicPV is building a 10 GW wafer plant, the largest in the U.S.

Southeast Asia had 35 GW of wafer factories in 2023. This will grow to 45 GW by 2024.

Qcells is investing $2.5 billion to make 3.3 GW of ingots, wafers, and cells each year.

These changes show the rising need for better solar panel production.

The next step is making solar cells. This turns silicon wafers into cells that create electricity from sunlight. Key steps include:

Texturing: Wafers are made rough to catch more sunlight.

Doping: Phosphorus is added to create an electric field.

Anti-Reflective Coating: A coating is added to absorb more sunlight.

Solar cells have different efficiency levels. Most panels are 15-20% efficient. High-end monocrystalline panels reach 20-22%, and the best ones go up to 23-25%. Special multi-junction cells can reach 40% efficiency but are very costly.

For example, a 1 m² panel with 20% efficiency makes 200 kWh/year in normal conditions. In sunny places like Colorado, it can make 400 kWh/year. In less sunny areas like Michigan, it makes 280 kWh/year, and in England, it drops to 175 kWh/year.

By improving each step, manufacturers make sure solar panels work well for many years.

The panel assembly step is when solar cells are put together to make a full solar panel. This part is very important because it affects how well the panel works and how long it lasts. But how are solar panels made during this step? Let’s break it into simple parts:

Solar Cell Arrangement:

Workers or machines place solar cells in a grid pattern. This setup helps the cells work together to make electricity. The number of cells depends on the panel's size and power needs. For example, home panels usually have 60 or 72 cells.

Interconnection:

Thin metal strips connect the solar cells. These strips let electricity move between the cells. The connections must be precise, as mistakes can lower efficiency. Soldering is used to secure these connections.

Lamination:

The connected cells are placed between protective layers. A clear EVA sheet is added on both sides of the cells. This keeps the cells safe from water and stress while holding them in place.

Glass Placement:

Tempered glass is added on top of the cells. This glass shields the cells from damage caused by weather, like hail or strong winds, while letting sunlight through.

Backsheet Addition:

A backsheet is attached to the bottom of the panel. It protects the inside parts from water, dirt, and sunlight, keeping the panel safe.

Quality Check:

Before moving forward, the panel is checked for problems. This ensures it meets standards for strength and performance.

The panel assembly process uses careful work and technology to make panels that last and produce clean energy. Knowing this step helps you see the effort behind solar panel creation.

Encapsulation and framing are the last steps in making solar panels. These steps make sure the panels are strong, weatherproof, and ready to use.

Encapsulation:

Encapsulation seals the solar cells and their layers together. Heat and pressure bond the EVA, glass, and backsheet into one unit. This keeps air and water out, which could harm the cells. It also makes the panel stronger and less likely to bend or crack.

Tip: Good encapsulation helps solar panels last longer. Bad sealing can cause layers to peel apart, lowering efficiency.

Framing:

After sealing, the panel gets an aluminum frame. The frame adds support and makes it easier to install the panel on roofs or the ground. Aluminum is used because it resists rust and handles outdoor conditions well. Frames also have holes to drain water and prevent damage.

Junction Box Installation:

A junction box is added to the back of the panel. This box holds the electrical connections and links the panel to an inverter or other panels. It is sealed to keep out water and dust.

Final Testing:

Before shipping, panels go through strict tests. These tests check how well the panel works, how strong it is, and how it handles weather. This ensures the panel meets industry rules and provides reliable energy.

Encapsulation and framing are key to making durable and efficient solar panels. By doing these steps carefully, manufacturers create panels that last for decades and provide clean energy.

5 Easy Steps to Check the Quality of Solar Panels

Quality control is very important in making solar panels. Careful testing makes sure panels meet rules and work well for years. By learning about these tests, you can see the hard work behind strong and reliable solar panels.

Testing standards set rules for how solar panels should perform. These rules check if panels stay strong in different weather. Important standards include:

IEC 60904-3: This rule explains how to measure solar panel performance. It uses special sunlight data to check accuracy.

High Temperature Conditions (HTC): Panels are tested at 75°C and 1000W/m². This checks if they work well in very hot weather.

Low Temperature Conditions (LTC): Panels are tested at 15°C and 500W/m². This shows how they perform in cold places.

IEC 61853: This rule tests panels in many weather types. It helps see how they work in real-life climates.

These rules make sure panels handle heat, cold, and sunlight. By following them, companies make sure their panels are good and dependable.

Testing procedures check if panels are strong and work well. Each test looks at a different part of the panel. Common tests include:

| Testing Method | What It Checks | Passing Requirement |

|---|---|---|

| Thermal Cycling | Power loss after heating and cooling cycles | Less than 5% power loss |

| Mechanical Load Testing | Strength under heavy pressure | At least 2400 Pa without breaking |

| Hail Impact Testing | Damage from ice ball hits | Less than 5% power loss after hits |

| Salt Spray Testing | Resistance to salty air | Little material damage after 96 hours |

| Power Degradation Rate | How much power is lost each year | Below 0.5% means great durability |

Other tests like Electroluminescence (EL) Testing find hidden cracks. IV Curve Testing checks how much energy panels make. Climate chamber tests copy bad weather to see if panels stay strong. These tests make sure panels are safe and high-quality before being sold.

By using these rules and tests, companies make sure solar panels are tough and reliable. This helps panels last long and give steady energy in all kinds of weather.

New technologies are changing how solar panels are made. Advanced panels like perovskite and thin-film types are improving. Perovskite-silicon tandem cells now reach 33.9% efficiency. This is better than older single-junction cells. Experts believe future panels could pass 40% efficiency soon. This progress comes from better materials and AI tools.

Energy storage is also getting better. New lithium-ion and flow batteries store solar energy well. AI and IoT systems help manage energy smarter. These tools keep panels working even in tough weather. Together, these innovations are helping solar energy grow worldwide.

Making solar panels eco-friendly is a big goal. By 2050, U.S. solar electricity may produce just 0.040 kg CO2-eq/kWh. This shows how solar energy helps the planet. In 2019, solar power made 680 TWh of electricity, or 2.5% of global energy. If countries meet climate goals, solar could give 24% of energy by 2050.

Recycling is also improving. Companies are finding ways to reuse silicon and aluminum. This reduces waste and lowers the environmental impact of making panels.

Automation is speeding up solar panel production. Machines do tasks faster and with fewer mistakes. AI tools boost efficiency by 20% and cut costs by half. Automated assembly lines make panels quickly and with good quality.

Companies using automation see big benefits. Over 73% of IT leaders report saving time on manual work. About 51% say costs dropped by 50%. These changes make solar panels cheaper and easier to get. This helps more people switch to clean energy.

Learning how solar panels are made shows their complex creation. From getting raw materials to building panels, every step matters. For example, getting materials uses about 30% of the energy. Making panels takes 2,000-2,500 kWh of energy each. Modern panels save this energy in 1-4 years and work for up to 30 years. This makes solar power a smart and eco-friendly choice.

| Step | Important Facts |

|---|---|

| Getting Materials | Uses ~30% of energy; involves mining silicon, silver, aluminum, and copper. |

| Making Panels | Needs 2,000-2,500 kWh per panel; uses green energy to lower pollution. |

| Energy Payback Time | Panels save their energy cost in 1-4 years; last 25-30 years. |

Careful testing ensures panels are high-quality. New ideas make them better and greener. Solar panel production helps clean energy grow and supports a healthier planet for everyone.

Solar panels usually work for 25 to 30 years. Taking care of them can make them last longer. They lose a little efficiency over time but still make energy for many years.

Making one solar panel uses 2,000 to 2,500 kWh of energy. Panels save this energy back in 1 to 4 years. This makes them a smart and eco-friendly option.

Yes, solar panels can be recycled. Factories reuse parts like silicon, aluminum, and glass. Recycling helps cut waste and makes production better for the planet.

No, solar panels are different in type and efficiency. Monocrystalline panels work very well but cost more. Polycrystalline panels are cheaper, and thin-film panels are light and bendable.

Broken panels don’t work as well but still make energy. Checking panels often helps find problems early. If badly damaged, they might need replacing to keep working properly.