Views: 0 Author: Site Editor Publish Time: 2025-07-03 Origin: Site

Photovoltaic silver paste is like the blood of solar cells. It moves electrical current through tiny printed paths. This special paste helps solar devices work better. It does this by making good contacts and lowering resistance. Tiny studies show glass frit in the paste melts and spreads when heated. This makes strong links that carry electricity well. New data shows better paste formulas help a lot. They make solar cells up to 0.75% more efficient. They also use 60% less silver. The table below shows important improvements from new photovoltaic silver paste:

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Efficiency Gain | Baseline | +0.75% absolute |

| Silver Consumption | 100% | 40% |

| Highest Average Efficiency | 20.67% | 21.42% |

Photovoltaic silver paste helps solar cells collect electricity well. It also helps carry electricity by making strong contacts. These contacts have low resistance.

Good silver paste makes solar cells work better. It also helps them last longer, even in bad weather.

The paste has silver powder, glass powder, and organic materials. Each part helps with conductivity, sticking, and how the paste is used.

Using thinner silver lines saves silver. Better paste formulas also save money and make solar cells work better.

Scientists keep working to use less silver. They also want to make the paste better. This helps make solar energy cleaner and cheaper.

Photovoltaic silver paste helps move electrons inside a solar cell. Sunlight hits the cell and makes free electrons. These electrons need a way to travel out of the cell. Silver paste makes thin lines on the cell’s top. These lines collect electrons and send them out.

Scientists have tested how well different pastes collect electrons. They used current density–voltage tests to compare screen-printed and thermally evaporated silver electrodes. The way the paste is put on and the layers under it change how electrons move. Adding layers like MoO3 can make power conversion efficiency about 40% better. This means the right paste and layers help collect more electrons.

Contact-end voltage tests also check how well the paste works. These tests show the paste must connect well with silicon. If the connection is strong, electrons move easily and the cell works better. The paste’s microstructure is important too. For example, Bi2O3 glass frit helps the paste make tiny silver crystals at contact points. These crystals act like tunnels for electrons. This lowers resistance and helps the cell work better.

Note: Good silver paste and its connection with silicon are important for high-efficiency photovoltaic cells.

Better solar technology needs better silver paste. High-quality paste helps electrons move fast with little loss. This makes solar cells work better and give more power.

Reliability is as important as efficiency in solar cells. Photovoltaic silver paste must last for many years, even in hard conditions. Engineers test the paste using strict rules like IEC 61215. These tests check if the paste can handle heat, cold, water, and sunlight without breaking.

Field tests show anti-PID silver pastes keep 98.2% efficiency after 12 months at 50°C. This means the paste can resist damage from heat and bad weather.

The paste must stick well to silicon. A strong bond of at least 2.0 N stops power loss over time.

Nano-silver particles in the paste help it stick 15% better. This lowers the chance of cracks when the temperature changes.

The paste must survive 1,000 heating and cooling cycles. This shows it can last through many years of daily temperature changes.

Good silver paste resists water and UV light, which often damage outdoor solar panels.

Reliable photovoltaic silver paste helps solar panels work well for a long time. This makes solar energy a good choice for clean power. As more people use solar panels, the need for strong and efficient silver paste grows.

Image Source: unsplash

Photovoltaic silver paste has three main parts. Each part helps solar cells work better.

| Component | Role in Solar Cells |

|---|---|

| Silver Powder | Gives high electrical conductivity. It helps collect current and improves efficiency. |

| Glass Powder | Acts as a binder during heating. It helps silver stick to silicon and forms a strong contact. |

| Organic Materials | Works as a binder and solvent. It makes the paste easy to apply and helps it stick to the wafer. |

Silver powder is the most important for cost and how well it works. The size and shape of the silver pieces matter a lot. Nano-silver lets the paste melt at lower heat and lowers resistance. Flake-shaped silver gives more area to touch the silicon and helps the paste connect better. Glass powder melts when heated and helps make a strong bond. Organic materials keep the paste smooth and help it stick before heating.

Note: Using the right mix of these parts lets the paste make thin, even lines on the solar cell. This helps collect more electricity and makes the cell work better.

Photovoltaic silver paste needs special features to help solar cells last and work well.

High electrical conductivity: Silver lets electrons move fast. This lowers resistance and helps collect more current.

Strong adhesion: The paste must stick well to the silicon wafer. Good sticking stops the lines from peeling or cracking.

Stable microstructure: How the silver pieces join during heating changes how the paste works. A stable structure means better results.

Good sintering activity: The paste should melt and bond at the right heat. This makes a strong, even contact with the silicon.

Long-term stability: The paste must resist water, sunlight, and heat. This keeps the solar cell working for many years.

Studies show the shape of the silver powder changes how the paste works. Polycrystalline silver powder melts at lower heat and gives good conductivity. Crystal growth silver powder needs more heat but makes smoother, more even lines. Both types can help solar cells work well if used the right way.

Photovoltaic silver paste uses these features to help solar cells turn sunlight into electricity. The right mix and structure make solar panels last longer and work better.

Manufacturers put photovoltaic silver paste on both sides of solar cells. Each side uses the paste for a different job. On the front, the paste makes thin lines called fingers. These fingers collect electricity from sunlight and move it out. Special printing methods make these lines even thinner. Thinner lines let more sunlight reach the cell. This helps the cell work better. For example, using a 15 μm finger instead of 20 μm saves 5 mg of silver. It also makes the cell 0.14% more efficient. DuPont and REC worked together to make PERC solar cells with special front paste. This helped REC’s TwinPeak panels win awards for high power.

The back of the solar cell uses silver paste in another way. Here, the paste connects the cell to the rest of the panel. It also helps with soldering. Some new designs use less silver on the back. They mix silver with copper or aluminum. One study showed copper can replace some silver on the back. The cell still works just as well. Using only aluminum made the cell a little less efficient. Other research found using less than 40% silver on the back saves 30% silver. This does not hurt how well the cell works or lasts. These changes help save money and materials.

| Application Side | Main Function | Silver Paste Focus | Efficiency Impact |

|---|---|---|---|

| Front | Collects and carries current | Fine lines, good contact | Higher with fine lines |

| Back | Soldering, connection | Lower silver, reliability | Maintained with blends |

Making thin lines and picking the right paste for each side helps solar cells work well, last long, and cost less.

There are two main types of photovoltaic silver paste. One is high-temperature and the other is low-temperature. High-temperature paste needs heat over 700°C to work. This process melts the glass and silver together. It makes strong, lasting bonds with the silicon wafer. Most regular silicon solar cells use high-temperature paste. This gives the best contact and helps the cell last a long time.

Low-temperature paste works at much lower heat, sometimes under 200°C. This type is used for new solar cells with special materials. Thin-film and organic solar cells need low heat so they do not get damaged. Low-temperature paste is also good for flexible solar panels and plastic parts.

High-temperature paste: Best for regular silicon cells, strong bonds, lasts long.

Low-temperature paste: Good for special or flexible cells, protects sensitive parts.

Picking the right type of photovoltaic silver paste depends on the cell’s design and what it is made of. This choice changes how well the cell works and how long it lasts.

Silver powder costs the most in photovoltaic silver paste. It is the main part that lets electricity move in solar cells. The price of silver powder goes up and down with the market. Many things can change this price, like new inventions, problems getting supplies, and government rules. The table below gives key facts about the silver powder market:

| Aspect | Details |

|---|---|

| Market Valuation (2024) | USD 2,169 million |

| Projected Market Size (2031) | USD 2,575 million |

| CAGR (2024-2031) | 1.9% |

| Key Components | High-purity silver powder, glass oxide, organic carrier |

| Product Segmentation | Front silver paste, Back silver paste |

| Manufacturing Process | Stirring, rolling, screen printing, drying, sintering |

| Cost Influencing Factors | Technology, supply chain, regulations, tariffs |

| Major Manufacturers | Heraeus, Samsung SDI, DuPont, KOKUSAI ELECTRIC |

| Tariff Impact | 2025 U.S. tariffs may change prices and supply |

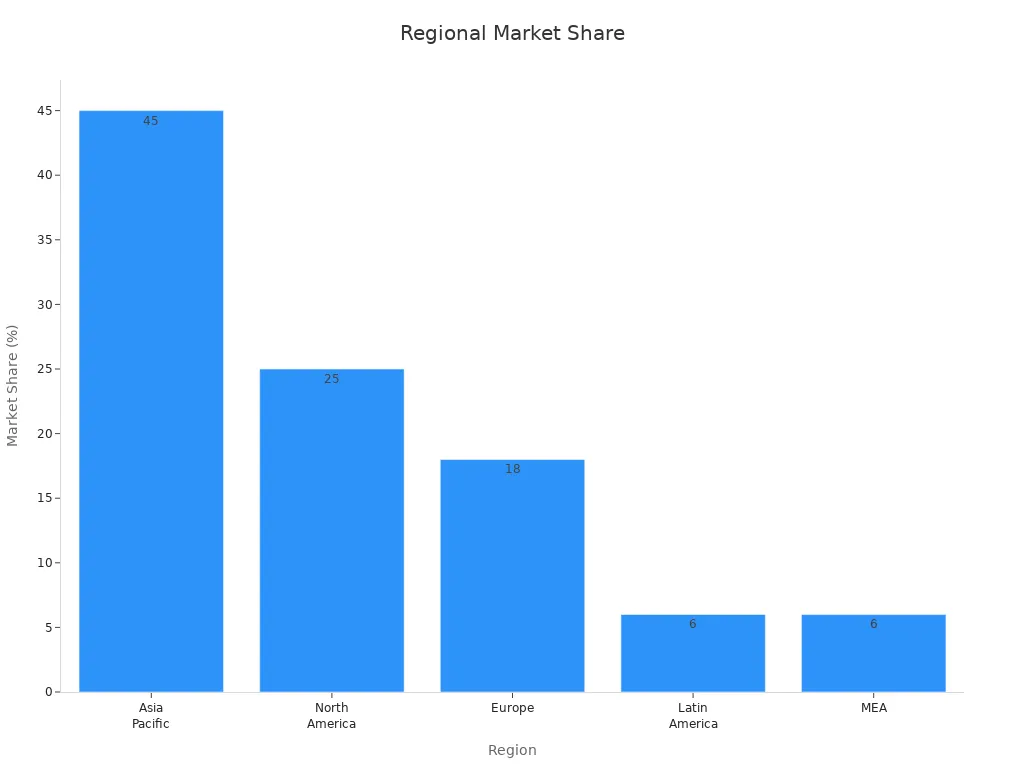

The kind of silver powder changes how much the paste costs. Spherical silver powder is used most, about 65% of the market. Flake silver powder is being used more because it works better in some solar cells. Asia Pacific sells the most, then North America and Europe.

How good and how much silver powder is in the paste changes how well a solar cell works. High-purity silver powder lets more electricity flow. Mixing different shapes of silver powder can make the paste work even better. This helps solar panels last longer and make more power.

Manufacturers want to use less silver powder to save money. Experts think silver use in solar cells will go down by 5–7% each year. Some people think new technology might replace silver paste by 2050. Companies like DuPont have made new paste that uses less silver but still works well. These changes help make solar energy cheaper and easier for everyone to use.

Scientists are working to make silver powder better for solar cell paste. They look at how the shape and mix of silver pieces change how well it works. New tests show that how much aluminum is used and how it reacts with air changes how silver and aluminum mix on silicon. This changes how good the metal contact is. Scientists also use a special method called capillary suspension to control how the paste moves. This helps them make thinner lines on solar cells. The shape of the silver and the kind of glass frit in the paste both matter for how well the paste spreads and sticks.

A new silver paste with a capillary suspension design gives better electrical results. It lets more current flow and lowers resistance in crystalline silicon solar cells.

The new paste works with both screen-printing and laser printing. This means it can make thinner and more exact lines.

Tests and computer models show these changes help solar cells work better and last longer.

These new ideas show where photovoltaic silver paste is going. Scientists want to use less silver but still make strong, reliable paste.

The solar industry is always changing as new cell types and ways to make them come out. Silver paste makers now make products for high-efficiency cells like PERC, TOPCon, and HJT. They work on printing thin lines, using lower heat, and using less silver. These changes help save money and make solar cells work better.

| Aspect | Evidence Summary |

|---|---|

| Alignment with Emerging Solar Technologies | Silver paste works with new cell types by helping make thin lines and using less heat. |

| Innovation Drivers | Paste makers and cell makers work together to make new products faster. |

| Market Growth Factors | Solar power is growing because of clean energy goals and new projects in places like China and India. |

| Sustainability and Alternatives | Companies try to make greener paste and test other materials like copper. |

| Forecast | The market will grow quickly as new solar cell designs and higher efficiency come out. |

Other trends are using nanoparticles to help electricity move better and use less silver. Some companies try 3D printing to put on paste in a better way. New rules want pastes to be safer and better for the environment. Most of the market is in Asia-Pacific, and China is the leader in making and using solar cells. As solar technology gets better, new silver pastes will help give the world more clean energy.

The solar cell industry uses special materials to make panels better. Silver paste helps solar panels work well and last a long time. New studies help make better paste and smarter designs. These changes help make energy cleaner and cost less. Scientists keep finding ways to use less silver but keep high efficiency. As technology gets better, more people will use solar power in the future.

Photovoltaic silver paste makes thin lines on solar cells. These lines pick up electricity from sunlight. The paste helps send the electricity out so people can use it.

Silver paste is safe when used in solar panels. Companies follow strict rules to keep things clean. Most of the silver stays inside the panel and does not hurt nature.

Solar panels need silver paste to work really well. Some new panels use less silver or try other metals like copper. But silver paste still works best for most solar cells.

| Benefit | Description |

|---|---|

| Higher Efficiency | New pastes collect more electricity. |

| Lower Cost | They use less silver. |

| Longer Life | They last longer in tough weather. |

New pastes help solar panels work better and last longer.