Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

EVA Panels Explained begins by telling what EVA means in solar panels. EVA is a clear and bendy sheet that covers solar cells. This sheet protects the cells from air, water, and dirt. EVA stands for ethylene-vinyl acetate. This material is bendy, see-through, and very strong. These features help EVA protect solar cells from sunlight and bad weather.

Studies show EVA and other layers help solar panels last longer. Check this table to see what scientists learned about these layers and how long panels work:

| Study Title | Key Findings |

|---|---|

| How Long Do Solar Panels Last? Decoding Degradation and Key Lifespan Factors | Chemical bonds in organic layers break when hit by sunlight. This makes the material weaker and less stable. It can also hurt how well the panel works. |

| Effect of Protective Layer on the Performance of Monocrystalline Silicon Cell for Indoor Light Harvesting | Polyethylene terephthalate (PET) blocks water and sunlight. It still lets light reach the solar cells. |

| UV LED ageing of polymers for PV cell encapsulation | Encapsulants help light pass through and keep electricity safe. They also protect from weather and keep the panel working for about 30 years. |

You can count on EVA to keep your solar panels strong and working for many years.

EVA is a clear and bendy sheet. It keeps solar cells safe from water, dirt, and UV rays. This helps the solar cells last longer.

Using EVA in solar panels helps them work better. It lets more sunlight reach the cells. This means the panels make more energy.

EVA panels make solar panels stronger. They block things like water and dust. This helps solar panels last for many years.

New EVA technology makes it even clearer and stickier. This helps solar panels work better and last longer.

EVA is used the most, but there are other choices. POE and TPU are new options. They can be better for some uses.

Have you ever wondered why solar panels last so long outside? EVA panels explained how they stay strong for years. EVA means ethylene-vinyl acetate. It looks like a clear plastic sheet. You find EVA inside every new solar panel. EVA protects solar cells from rain, dust, and sunlight. It works like a shield. It helps the cells keep working well.

EVA is part of the thermoplastic family. You can shape it when it gets hot. It stays bendy even when it is cold. The chemical formula for EVA is (C2H4 · C4H6O2)n. EVA is used in many things. In solar panels, it does something special. It lets sunlight go through but blocks bad stuff.

Here is a table that shows the main properties of EVA:

| Physical Property | Value |

|---|---|

| Chemical Composition | (C2H4 · C4H6O2)n |

| Density (kg/m3) | 930 to 950 |

| Glass Transition Temp (°C) | -30 to -15 |

| Melting Point (°C) | ~75 to 120 |

| Polymer Family | Thermoplastic |

| Refractive Index | 1.48 to 1.51 |

EVA panels explained why this material matters. It is strong, bendy, and clear. This layer keeps solar cells safe and working for a long time.

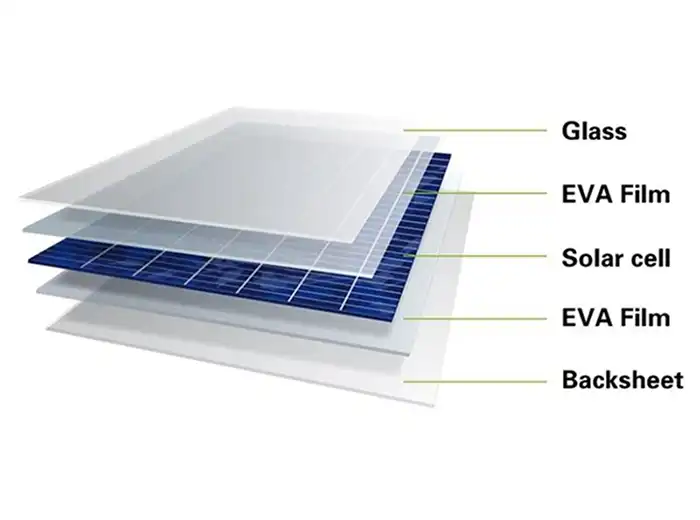

If you look inside a solar panel, you see layers. EVA panels explained how these layers work together. The EVA sheet sits above and below the solar cells. It holds the cells in place. It seals them from air and water.

The main parts of commercial EVA sheets are:

Ethylene vinyl acetate (EVA): This is the main part. It protects solar panels from strong sun rays.

Transparency: The sheet lets sunlight reach the solar cells.

Adhesive properties: EVA sticks to the glass and keeps the cells together.

You also find EVA sheets between the glass and the back plate. The frame goes around the edge. This design keeps everything safe.

EVA panels explained how the sheet helps solar panels work well. Here are some features:

High sunlight transmission: You get more energy from the sun.

Low degradability: The sheet keeps cells safe from dirt and wetness.

High peel strength: EVA holds the cells tight.

Low shrinkage: It stops damage during making.

Integrated UV protection: The sheet blocks harmful rays.

EVA panels explained why you need a strong, clear, and sticky layer. The sheet helps solar panels work better and last longer.

EVA sheets also have these qualities:

Adhesion: The sheet sticks the layers together.

High clarity: It lets light reach the cells.

Good UV degradation resistance: The sheet stands up to sunlight and weather.

Good EVA sheets last through tough weather. They help solar panels work well by letting in light and stopping wetness and UV rays.

You might wonder why makers use EVA in solar panels. EVA panels explained why they pick this material. EVA film covers the solar cells and keeps them safe from water, UV light, and heat. It is the most common material for covering solar cells.

EVA panels explained the good things about using EVA:

It covers solar cells between the back plate and glass.

It stops air and water from reaching the cells.

It protects against UV light and heat.

This makes solar panels last longer and work better. EVA panels explained how this material is cheap and works well. Other materials like TPO, POE, silicones, and ionomers do not break down as fast and do not turn yellow. But EVA is used most because it works well and costs less.

Here is a table that compares EVA with other materials:

| Encapsulant Material | Advantages | Disadvantages |

|---|---|---|

| EVA | Good balance between performance and cost | Degradation issues, acetic acid formation, yellowing |

| TPO, POE, Silicones, Ionomers | Lower degradation, less discoloration | Not as widely adopted as EVA yet |

EVA panels explained why you see this material in almost every solar panel. It keeps the cells safe, lets sunlight in, and helps the panel last for many years.

When you look at a solar panel, you see glass and metal. But inside, the important work happens. The eva encapsulation film wraps around the solar cells. This layer sticks the cells together and keeps them safe. It protects from sunlight, rain, and dust. Encapsulation stops damage before it starts. The film acts like a shield. It blocks harmful UV rays and helps the cells work well.

The table below shows how eva encapsulation film protects solar cells:

| Function of EVA Encapsulation | Description |

|---|---|

| Protection from UV Radiation | Controls UV rays so solar cells do not get weaker. |

| Moisture Barrier | Stops water from getting in and hurting the cells. |

| Mechanical Stability | Makes the panel stronger so it lasts longer. |

You need eva to keep your solar panels strong and working well.

You want your solar panels to last a long time. The eva encapsulation film acts as a water vapor barrier. It blocks air, moisture, and dirt from reaching the solar cells. Without this layer, water and dust could break down the cells. This would lower the power output. Encapsulation keeps the inside clean and dry. The eva sheet seals the cells tightly. It stops water vapor and dirt from getting in.

Encapsulation is important for solar panel performance. It keeps moisture and dirt out. Your panels keep making electricity year after year.

The eva encapsulation film does more than protect. It helps your solar panels work better. The cross-linking reaction inside eva makes a strong network. This network gives chemical, mechanical, and optical stability. Your panels can handle heat, cold, and stress.

The cross-linking reaction in eva makes the panel stronger.

Higher gel content means the panel lasts longer.

Gel contents above 84% give good stability. Lower levels can make the panel break down faster.

Encapsulation also helps the panel work better. More light reaches the cells. You get more electricity and safer operation. The table below shows how performance improves with eva encapsulation film:

| Metric | Before Optimization | After Optimization | Improvement |

|---|---|---|---|

| Efficiency (%) | 16.5 | 21.1 | +4.6 |

| Short-circuit current density (mA/cm²) | 34.3 | 38.2 | +3.9 |

| Open-circuit voltage (mV) | 632 | 684 | +52 |

| Fill factor (%) | 76.2 | 80.8 | +4.6 |

You get better results and longer life when you use eva encapsulation film as a water vapor barrier in your solar panels.

Solar panels need to bend a little. EVA helps them do this. It lets panels flex without breaking. This is good for temperature changes and small bumps. EVA absorbs shocks and keeps solar cells safe.

Tests show EVA absorbs about 5.4 kJ/m² of impact.

Polyolefin absorbs more, about 12.9 kJ/m². But EVA still protects solar panels well.

EVA’s flexibility helps panels last longer, even in bad weather.

Solar panels need sunlight to make power. EVA is very clear. It lets lots of sunlight reach the cells. Less light gets scattered, so panels make more energy.

Clear EVA means better panel performance.

Good light transmission is a key EVA property. It helps panels work better.

Tip: Clearer EVA helps your panels make more power!

Rain and dust can hurt solar panels. EVA blocks water and dirt. It seals the cells and keeps moisture out. This keeps panels working for years.

EVA stands up to weather changes.

It keeps the inside of panels dry and safe.

EVA does more than block water and shocks. It also keeps electrical parts safe. EVA insulates the cells and stops short circuits.

When panels are made, EVA forms a sealing layer.

The panel has glass, two EVA sheets, solar cells, and a back sheet.

Good EVA and proper curing protect the circuits.

EVA gives safety and helps panels work well.

When you look at eva panels, you see layers stuck together. Lamination is the process that makes these layers bond. First, you stack five layers: glass, eva, solar cell strings, eva, and a back sheet called TPT. The stack goes into a lamination machine. The machine heats everything to about 135°C for 22 minutes. During heating, eva melts and spreads out. The cross-linking agent inside eva breaks apart and makes free radicals. These free radicals help long molecules join together. This turns the layers into one solid sheet.

There are three main steps in lamination:

Heat the module so eva can cross-link.

Use a vacuum to pull out air and stop bubbles.

Press the layers so eva sticks to the glass and cells.

The amount of cross-linking agent and the temperature matter for bonding. Clean surfaces and good settings help eva stick better. If you add more vinyl acetate to eva, it sticks stronger. But you need to watch for possible problems.

Tip: Good lamination helps eva panels last longer and work well in tough weather.

You want eva panels to last for many years. Quality control checks every step in making them. Tests include flash testing for power and EL imaging for cell damage. Insulation resistance testing keeps you safe from electrical problems. Visual checks find small defects and make sure labels are right.

Manufacturers use special tools:

Automated Optical Inspection (AOI) finds tiny problems.

X-ray Inspection looks inside the panel without opening it.

Thermography finds hot spots that could cause trouble.

Data analytics helps make production better.

Eva is used to seal and protect solar cells. You also see eva in packaging and shoes. In solar panels, you need to stop micro-cracks, seal well, and lower damage. Strong frames and careful handling help keep cells from breaking.

Here is a table with common defects and how to fix them:

| Defect | Causes | Mitigation Strategies |

|---|---|---|

| Solar cell crack | Force, temperature changes | Avoid bumps, preheat cells |

| EVA insoluble | Old eva, bad heating | Check materials, control heating |

| Bubble | Dirt, old eva | Clean area, use fresh eva |

| Foreign matter | Dust, pollution | Keep area clean, handle materials carefully |

You want eva panels to last outside for many years. Sunlight and temperature changes test their strength. UV rays break down eva and make it weaker over time. Big temperature swings can cause tiny cracks and let water in. Picking eva with good thermal stability helps panels survive these problems.

Eva is used in solar panels for durability. Panels resist humidity, salt mist, and stress. Manufacturers test panels with heat and freeze cycles. These tests make sure eva panels stay strong and work well, even in tough places.

Note: Choosing good eva and using strong quality control keeps your solar panels working for a long time.

When you use eva in solar panels, you need to watch for some problems. Sometimes, eva can lose its grip and the layers peel apart. This is called delamination. Bubbles can also form inside the panel. These bubbles are called blisters. They stop heat from leaving and block sunlight from reaching the cells. Another problem is fading. The eva can turn yellow or cloudy. This means less light gets through and the panel makes less power.

Delamination: Layers come apart and water can get in.

Blistering: Bubbles show up and block sunlight.

Fading: The color changes and the panel works less well.

You can stop these problems if you are careful. Here are some tips in the table:

| Precaution | Description |

|---|---|

| Moisture Control | Keep eva dry so bubbles do not form and layers stay strong. |

| Dust Control | Clean the surface so dust does not block light or make the bond weak. |

| Proper Handling | Wear gloves so you do not get oil on eva. |

| Storage | Store eva below 30°C and under 60% humidity. |

| Covering | Cover extra eva pieces to keep out air and water. |

New types of eva make solar panels work better. These new kinds are clearer, stick better, and handle heat well. Some let more sunlight reach the cells. Others stick better to glass and silicon, so water stays out. Scientists are making eva that stands up to UV rays and lasts longer outside.

| Property | Description |

|---|---|

| Optical Properties | Very clear eva lets in more sunlight and helps the panel work better. |

| Adhesive Qualities | Strong glue keeps water out and protects the solar panel. |

| Thermal Stability | Better heat resistance helps panels last in hot places. |

| Ongoing Innovations | New eva types are made to block UV rays and be better for the environment. |

These new eva types keep heat in, last longer, and make more energy than old ones. Some people still worry about how they last over many years, but most panels work better with these new kinds.

| Aspect | New Formulations of EVA | Traditional EVA |

|---|---|---|

| Thermal Insulation | Better | Regular |

| Durability | Lasts longer | Lasts a normal time |

| Energy Efficiency | Makes more energy | Makes less energy |

| Long-term Performance | Some worries | Usually stays stable |

Sometimes, companies use other materials instead of eva. This happens when eva costs more or new ideas come out. Some other materials are POE, EPE, polyurethane films, polyaspartate polyurea, and TPU-based systems. These new materials help panels last longer and work in new ways, like in bifacial panels. More companies are making these non-eva products now.

| Alternative Material | Description |

|---|---|

| POE | Polyolefin film that fixes some eva problems. |

| EVA-POE-EVA (EPE) | Mixes eva and POE for better results. |

| Polyurethane films | Hot-melt glue for strong and safe panels. |

| Polyaspartate polyurea | Barrier that makes panels last longer. |

| TPU-based systems | Flexible cover for new kinds of solar panels. |

Bifacial solar panels use two layers and flexible covers. These new materials can cost more at first, but they can save money over time. If eva prices go up, these other choices become even more popular for big solar panels.

You count on eva panels to keep your solar panels working well. Eva helps your panels stay strong and last longer. It lets more light reach the solar cells. Eva also protects panels from water and sunlight. New materials, like self-healing polymers and polyolefins, make panels tougher. These materials help panels make more energy. Scientists are working on options that are better for the planet. Good encapsulation keeps your solar panels safe and working for years.

| Aspect | Importance |

|---|---|

| Mechanical Integrity | Makes solar panels steady and safe for a long time. |

| Optical Transparency | Lets more sunlight reach the cells for better power. |

| Environmental Resistance | Protects panels from water and sunlight, so they last longer. |

Smart encapsulation, like eva and new materials, helps solar panels last longer.

You get better solar panels because of new ideas and improvements.

EVA means ethylene-vinyl acetate. It is a clear and bendy sheet. You see it inside most solar panels. This sheet protects the solar cells. It helps them last a long time.

EVA works like a shield. It keeps water, dirt, and sunlight away. This layer protects the solar cells. It helps them work well for many years.

EVA can turn yellow after years in the sun. When this happens, less sunlight gets through. The panel makes less power. New EVA types do not turn yellow as fast.

You can recycle EVA in some places. Not every area has recycling for EVA. EVA does not make harmful chemicals when used. Makers are trying to make EVA safer and greener.

Other materials like POE or TPU are used.

These choices may last longer or work better in some panels.

EVA is still the most common because it costs less and works well.

Top 7 TOPCon Solar Panels That Outperform Traditional Bifacial Modules

TOPCon Solar Panels: The Next Evolution Beyond Bifacial PERC Technology

PERC Solar Cell Technology: The Foundation of Modern Bifacial Solar Modules

Hybrid Solar Solutions: Combining Off-Grid and On-Grid Solar Technologies for Maximum Efficiency

Designing the Perfect Off-Grid Solar Array: Size, Configuration, and Optimization Strategies

Bi PV Systems: Installation, Performance Metrics, and ROI Calculations