Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

You can use electroluminescence inspection to find hidden problems in solar cells. Normal visual checks often miss these issues. This method uses the electroluminescence effect. It makes defects like microcracks and cell damage easy to see. This helps you find problems early. EL inspection is very important for checking the quality of photovoltaic modules. Finding defects early protects your solar investment. It also helps you get more solar energy. Inspections with AI give very accurate results.

Finding defects early in solar panels makes them better and lowers the chance of warranty problems.

Inline and offline inspection systems let you check each solar cell before it is shipped.

Electroluminescence (EL) inspection finds hidden problems in solar panels. These problems include microcracks and cell damage. Visual checks often do not find these issues.

Regular EL testing keeps solar panels working well for a long time. It finds problems early. This stops expensive repairs and warranty claims.

Automated analysis with AI makes finding defects faster and more accurate. This helps control quality in big solar panel factories.

Using EL inspection in factories and in the field keeps solar panels in good shape. This helps them make more energy and protects your money.

Buying good EL testing tools and doing regular checks makes solar energy systems work better and last longer.

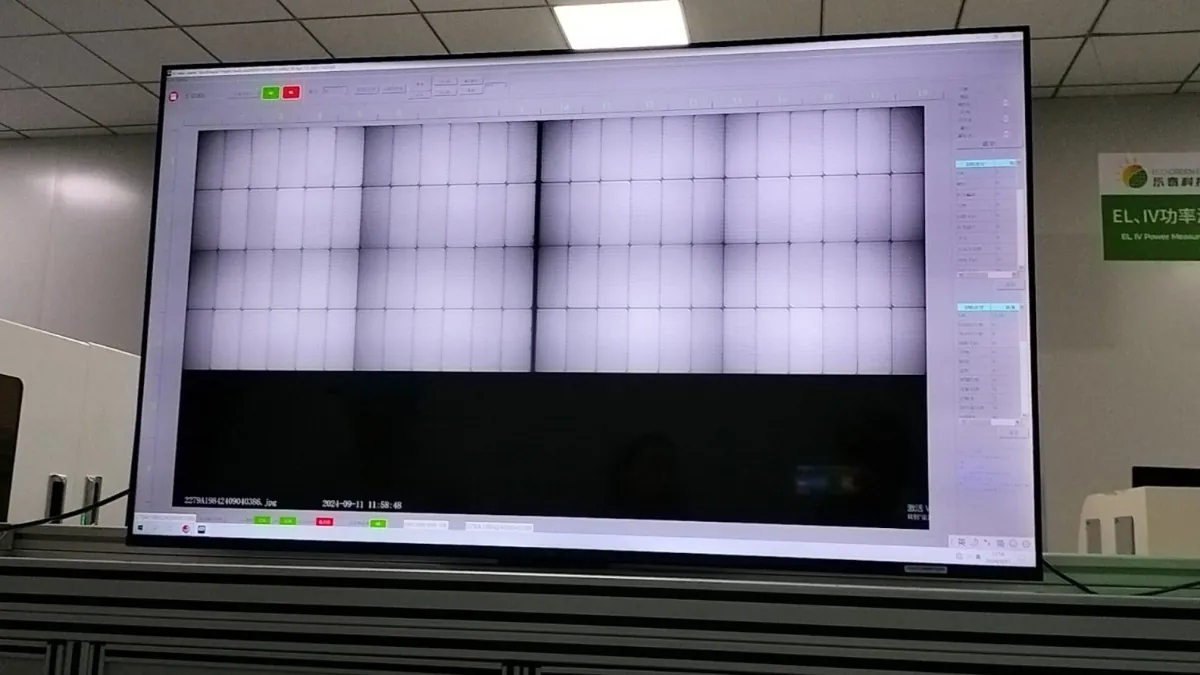

You can use electroluminescence inspection to find hidden problems in solar panels. This method works by putting a special voltage on the photovoltaic cells when it is dark. The cells then give off a weak infrared light. A special camera takes a picture of this light. You can see cracks, broken cells, and other problems that you cannot see with your eyes.

Let’s see how electroluminescence compares to other ways to test solar panels:

| Testing Method | Key Principle | Advantages | Limitations |

|---|---|---|---|

| Electroluminescence (EL) | Applies forward bias voltage in darkness to emit IR light | Non-destructive, high sensitivity to defects | Needs special equipment |

| Infrared Thermography | Finds temperature changes | Fast check for heat problems | Does not show where all defects are |

| I-V Curve Tracing | Checks electrical performance | Gives performance data | Does not show where defects are |

| Visual Inspection | Looks for surface problems | Easy and fast | Only finds what you can see |

| UV Fluorescence | Shows some material properties | Good for checking materials | Gives different info than EL |

| Photoluminescence | Uses light to study cells | Like EL but uses different light | May not show as many details |

You can see that electroluminescence shows more about the inside of a solar panel than other tests.

You want your solar panels to last and make lots of energy. EL inspection helps you do this. This test finds small cracks and problems before they get worse. You can fix things early and stop your solar system from losing power.

Electroluminescence imaging is fast and does not hurt the solar modules. If you use machine learning to look at EL images, you get even better results. This way finds problems better than just looking or using heat cameras. You can trust EL inspection to keep your solar panels safe and working well.

Tip: Doing EL inspections often helps you find hidden problems and keeps your solar panels working their best.

You begin by getting your solar PV modules ready for testing. You must follow steps to make sure results are correct. Here is a simple guide:

First, disconnect the PV modules from the inverter and DC circuits. This stops unwanted current during the test.

Next, connect a DC power supply to the modules. Use a forward bias so the cells give off faint infrared light.

Put the EL camera where it can see all the modules. Make sure the camera covers the whole area you want to check.

You need to watch some things to get good images. The table below shows what you should look out for:

| Factor | Description |

|---|---|

| Ambient light interference | Sunlight makes it hard to see, so you may need shields or better processing. |

| Temperature fluctuations | Changes in temperature affect how the cells work and glow. |

| Weather dependence | Rain, wind, and humidity can move equipment and mess up connections. |

| Logistical constraints | Portable tools help you check big solar fields fast. |

| Signal-to-noise ratio | Weak infrared signals can get lost in outside noise. |

| High ambient light levels | Special filters or sensors help you see EL signals. |

| Exposure time constraints | Short exposure times stop too much light in the day. |

| Equipment limitations | EL systems for daylight cost more and are not as common. |

| Image post-processing | You must fix and improve images to get good data. |

| High image volume | You may need 100 to 300 pictures for each module in daylight. |

Tip: You get better results if you test in the dark. If you must test in daylight, use special tools and image fixes.

You use special cameras to take electroluminescence pictures. The equipment you pick depends on what you need. Here are some common systems:

| Equipment Name | Description | Application |

|---|---|---|

| CellSpot | Made for small or medium areas in a dark room | Electroluminescence data capture |

| PanEL-Spot | Lab system for taking pictures of solar cells and panels | Electroluminescence imaging |

| TravEL-Spot | Used for taking pictures in the field or inside | Electroluminescence imaging |

High-resolution cameras let you see tiny cracks and problems. Low-resolution cameras might miss these defects. You find more defects with better resolution. EL imaging uses a filter to block normal light. This makes the electric field patterns easier to see. You can use still or moving pictures to find and study defects fast.

After you take the pictures, you need to look at them to find problems. There are different ways to study the results. The table below shows some common methods:

| Method | Description | Accuracy and Speed Characteristics |

|---|---|---|

| Fast Fourier Transform | Changes signals to find peaks and patterns. | Very accurate for certain frequencies; fast automatic checks. |

| Automated Classification | Uses neural networks to spot defects and sort cells. | Very accurate; speed depends on how well the program is trained and the data. |

AI software makes checking much faster and more trustworthy. Tools like SELMA can scan thousands of modules in seconds. You can find over 15 kinds of defects with more than 99% accuracy. AI helps you see micro-cracks and small problems that people miss. You get the same results every time and save time compared to checking by hand.

Note: Using AI makes your checks faster and more accurate. You can trust the results for big solar panel tests.

Electroluminescence inspection does not hurt the modules. You do not damage them when you test. You can use this method for regular checks and quality control. You get lots of details about your solar panels’ health and can fix problems quickly.

Electroluminescence testing helps you see hidden problems in solar panels. These problems can make your panels work less well. You can find issues early and fix them before they get worse. This method does not hurt your solar panels. It helps keep your solar energy system working well.

With electroluminescence testing, you can see microcracks and cell damage. You cannot see these with your eyes. These cracks can happen when the panels are made, shipped, or put in place. Sometimes, normal use causes them too. EL images show these cracks as dark lines or spots.

Here is a table that shows how well different methods find microcracks:

| Detection Method | Detection Rate (%) |

|---|---|

| Conventional EL | 67 ± 15 |

| PL | 74 ± 18 |

| High-resolution EL | 84 ± 3 |

Electroluminescence testing does not find every crack. It can miss 16–33% of cracks in solar cells. If the image is not clear, it misses more cracks. This happens a lot in big PV modules.

Note: Microcracks can show up at any time, from making to using the panels. EL inspection helps you find problems early, but you should not use it alone for long-term checks.

Microcracks can cause many problems for your solar panels:

Microcracks make it harder for electricity to move. This makes the cells hot and can cause hotspots.

Hotspots hurt the cells over time and lower power.

Cracks can get bigger and block parts of the cell. This causes more heat and problems.

These cracks are places where charge carriers meet and stop working. This makes the EL images look darker.

Uneven heat from cracks can make them spread. This makes your solar panels less reliable.

If you do not find microcracks, you lose power and efficiency. Your solar energy system will not work as well. You might need more repairs.

Electroluminescence testing also helps you find problems with soldering and how the panels are made. These problems can make your panels lose power or stop working.

Here are some common defects you might see in EL images:

| Defect Type | Description |

|---|---|

| Microcracks | Small cracks that can hurt cell performance. |

| Cell cracks | Bigger cracks that cause more problems. |

| Soldering defects | Bad solder joints that can cause electrical failures. |

| PID defects | Potential Induced Degradation that lowers how well the module works. |

| Dead cell | Cells that do not make electricity, so you get less power. |

| Short circuit | Electrical problems that can make the module fail. |

| Disconnections | Lost connections between cells that lower performance. |

| Shifting problems | Cells that are not lined up right, which lowers efficiency. |

You might see cold soldering, bad joints, or connections that waste energy as heat. Sometimes, bypass diodes turn on and cut off a cell. You can see this as a dark spot in the EL image.

These problems can cause:

| Failure Mode | Impact on Performance |

|---|---|

| Solder Joint Degradation | Power loss in PV modules, lower efficiency |

| Cracking of Interconnections | Up to 40% of failures, early loss of efficiency |

| Thermal Cycling Effects | More stress, more cracks, higher resistance, and hot spots |

| Delamination and Corrosion | Up to 4% power loss, bigger problems if not fixed |

| Cell Cracks and Broken Interconnections | No set limit on power loss, can fail before warranty ends |

If you ignore these defects, you can lose a lot of power. Your solar panels might stop working before the warranty ends. Regular checks help you find these problems early.

Electroluminescence testing lets you find shunting and other strange problems in your solar panels. Shunting happens when electricity takes a shortcut. This means it skips parts of the cell and lowers power.

You can find these problems in EL images using different ways:

| Anomaly Type | Identification Method |

|---|---|

| Microcracks | Shape analysis and diffusion patterns |

| Finger Interruptions | Automated detection with binary clustering |

| Electrically Isolated Cells | Show up as dark areas in EL images |

| Surface Irregularities | Fourier transform analysis |

| Deep Learning Techniques | CNNs for automatic defect classification |

You might see dark spots or lines. These show where electricity does not flow right. Deep learning models, like convolutional neural networks (CNNs), help you find these problems faster and better than checking by hand.

Deep learning makes EL images clearer and easier to check.

CNN models sort defects by themselves, so checks are faster.

When you find shunting and other problems early, you stop bigger issues. Your solar panels stay strong, and you get more from your solar energy.

Tip: Regular electroluminescence testing helps you find hidden problems, keep your system working well, and protect your investment.

When you look at electroluminescence images, you have two choices. You can check the images by hand or use a computer. If you do it by hand, you or a trained worker look at each picture. People see things differently, so results can change. You might miss small problems if you get tired. Checking by hand also takes a long time, especially with many panels.

Automated analysis uses computer programs and deep learning. These systems, like PV-YOLOv12, find problems fast and very well. Computers do not get tired or bored. You can use automated checks for big jobs and quality control. This makes your checks quicker and more trustworthy.

Here is a table that shows the main differences:

| Aspect | Manual Analysis | Automated Analysis |

|---|---|---|

| Time Efficiency | Time-consuming and slow | Significantly faster due to automation |

| Accuracy | Inconsistent results due to human error | Improved accuracy through advanced techniques |

| Staff Requirement | Requires specially trained staff | Reduces need for specialized training |

| Application Scope | Not efficient for large-scale production | Suitable for large-scale production and quality control |

Automated analysis helps you keep your solar panels working well. It finds problems early and fast.

When you test, you need to know what to look for in the pictures. Some patterns and marks show where the problems are. You can spot these signs in electroluminescence images:

| Defect Type | Description |

|---|---|

| Crack Pattern | Various patterns of cracks observed. |

| Broken Cell | Partially damaged solar cell. |

| Interruption of Finger | Breaks in the electrical connections. |

| Shunt Fault | Faults causing short circuits. |

| No Defect | Normal functioning cell. |

You should look for dark lines, spots, or broken parts. These signs mean your solar cells may not work right. Regular checks help you find these problems before they get worse. If you use automated analysis, you find defects faster and more accurately.

Tip: Always look for these signs during el inspection. This keeps your solar panels working their best.

You want every solar panel to be good before it leaves the factory. Electroluminescence testing helps you find hidden problems while making panels. You can see micro-cracks and other defects early. This stops you from sending out bad panels. You check for issues when making cells and building the whole module. You make sure each panel works well and keeps customers happy.

Electroluminescence helps you find micro-cracks and defects that normal checks miss.

You test panels during cell making and module building.

You make the final solar product better.

This method does not hurt the panels. You catch problems before they get worse. If you find defects early, you can fix them fast. This lowers the chance of losing power and helps panels last longer. EL inspection stops surprise failures and keeps defect numbers low.

You find microcracks before they cause big trouble.

You see soldering problems and other hidden issues.

You help panels work better and last longer.

You also use electroluminescence testing outside the factory. Field checks help you look at panels after shipping, installing, or storms. You can see if weather or handling caused damage. This testing gives proof if you need to ask for a warranty repair.

You use field testing to find defects and check how panels work.

You spot damage from making, shipping, installing, or weather.

EL testing helps you fix problems fast. You keep your solar system working well and protect your money. Field checks let you fix issues before they get worse.

Tip: Regular field testing helps your solar panels work their best and gives strong warranty support.

You need special tools for electroluminescence testing. Each tool does something important. The table below shows the main parts and their jobs:

| Feature | Description |

|---|---|

| Camera | 24.3 MP resolution, customizable filters |

| Power Supply | Up to 3A or 5A, 60V DC output |

| PL Lamps | 100W green or red LED, variable intensity |

| EL Probing Station | Supports up to 16 bus bars, max cell size 230x230 mm |

| Software | IMPEL for device control and image processing |

| Illumination | Full-area LED, no safety risks from lasers |

| Customization | Options for larger sizes and specific needs |

A high-resolution camera helps you see tiny details. The power supply gives steady voltage to the cells. PL lamps help you spot different problems. The probing station keeps the cells in place. Special software runs the devices and helps you look at pictures. Full-area LED lights make testing safe. You can change the setup for bigger panels or special needs.

Good electroluminescence testing tools have smart features. These features help you work faster and get better results:

High-resolution, automatic systems make testing simple.

Artificial intelligence finds problems fast and correctly.

You can change speed and resolution for different jobs.

You can test big modules up to 1400 x 2750 mm.

These features help you find problems early. Your solar panels work better and last longer. You can trust the results and make good choices for your solar system.

Tip: Pick equipment that fits your testing needs. Good tools help you find hidden problems and keep your solar panels safe.

You need to take care of your solar panels to get more energy. Regular testing helps you find problems before they get worse. Electroluminescence testing lets you see tiny cracks and defects you cannot see with your eyes. If you find problems early, you can fix them fast. This helps your solar panels last longer and work better.

Here are some ways routine electroluminescence testing helps you:

You can find micro cracks and hidden defects in your solar panels.

You can fix problems early by doing maintenance before things break.

Your solar panels will last longer and work better.

Tip: Test your solar panels often. This keeps your system strong and saves you money in the long run.

When you test your solar panels, you might find some common problems. Microcracks can show up in PV cells. These cracks can happen when the panels are made, shipped, or put in place. Bad weather, like hail or strong wind, can also cause cracks. Microcracks can make your panels lose power and not work as well.

You might see these signs:

The I-V curve looks stepped or uneven, which means the current does not match.

The current is lower than what you expect.

To fix these problems, you can:

Use I-V curve tracing to see if the curve has changed.

Use electroluminescence inspection to find microcracks with a reverse bias current.

Try infrared imaging to find hot spots that show where microcracks are.

Replace any modules that have bad microcracks.

Field checks help you find these problems early. If you test and fix things quickly, your solar energy system will keep working well.

Note: Always look for microcracks and other hidden problems when you test your solar panels. This keeps your investment safe and your solar panels working well.

AI and automation will change how we check solar panels. These tools help you find problems faster and more easily. AI uses computer vision and machine learning to spot things people might miss. You can use these systems to check many panels at once. This makes making solar panels better and faster.

Here are some ways AI and automation help with solar testing:

AI finds and shows where defects are in solar panels.

CPUs, FPGAs, and GPUs help process the images.

New image methods work with special machine learning hardware like TPUs.

| Advancement Type | Description |

|---|---|

| AI Algorithms | AI finds and locates defects in solar panels. |

| Hardware Systems | CPUs, FPGAs, and GPUs run image processing. |

| Future Directions | New image methods made for machine learning hardware like TPUs. |

AI-powered checks give you better results and save time. You can trust these systems for checking lots of solar panels.

You can make solar panel checks better by using more than one test. When you use different tests together, you see more and find more problems. For example, you can use electroluminescence with thermal imaging or non-DC polarization. This helps you know more about your solar panels.

| Aspect | Traditional DC Methods | Non-DC Polarisation |

|---|---|---|

| Defect Detection | Finds only some defects using current | Finds more types of defects in one scan |

| Image Quality | Hard to see small problems | Easier to see small problems and clearer images |

| Testing Efficiency | Needs many tests for different problems | Checks for many problems in one scan |

You get better results when you use more than one test. This helps you find hidden problems and keep your solar panels working well.

More solar companies will start using these new testing tools. This means you can keep your solar panels safe and get more energy from them.

You get lots of good things when you use electroluminescence inspection for solar panels. This way helps you find microcracks, check problems better, and make sure your panels are good quality. Look at the table below to see the main benefits:

| Benefit Type | Description |

|---|---|

| Defect Detection | Finds micro-cracks and hidden damage in solar modules. |

| Analysis Accuracy | Computer models improve how you find and classify defects. |

| Quality Assurance | Helps you judge the health of each cell and the whole module. |

You should test your solar panels at every step. Cracks, bad weather, and old age can cut power by almost half. New tools let you check panels outside and after storms. Always learn about the newest testing tools and tips to keep your solar panels strong.

New EL testing uses smart cameras and computer programs.

You can now check solar panels outside the lab and get results faster.

Keep learning about new ways to test. This helps you keep your solar panels safe and get more energy.

You use electroluminescence testing to see hidden problems in solar panels. This test shows cracks and defects that you cannot see with your eyes. You get a clear picture of your panel’s health.

You should check your solar panels with EL testing once a year. You can also test after storms or if you see a drop in power. Regular checks help you find problems early.

Yes, you can use EL inspection both in the lab and out in the field. Portable systems let you test panels after installation or during maintenance. You get fast results wherever your panels are.

EL images show microcracks, broken cells, bad solder joints, and shunting. You can spot these problems before they cause big power losses. Early detection helps you keep your system strong.

No, EL testing does not harm your solar panels. The process uses a safe voltage and special cameras. You can test your panels many times without causing any damage.

2025 Half-Cut Solar Panel Market Analysis: Trends, Growth Projections, and Leading Manufacturers

Solar Panel Inspection Services: Ensuring Peak Performance and Longevity

Translucent PV Panels: The Complete Guide to Technology, Applications, and Future Potential

PV Panel Specifications: Understanding Solar Panel Technical Parameters

How to Calculate PV Panel Efficiency: Step-by-Step Guide with Formulas and Examples