Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

You need to know about the pv 85 c threshold to keep solar modules safe. When a module gets this hot, fire risk goes up and it works less well. International rules say 85°C is a very important temperature. For example, tests use 85°C and 85% humidity for 1000 hours to see if modules last. The table below shows normal test conditions for pv modules:

| Test Type | Temperature Range | Duration |

|---|---|---|

| Cycling Temperature Limits | -40°C ± 2°C to +85°C ± 2°C | N/A |

| Damp-Heat Test | 85°C ± 2°C with 85% RH | 1000 hours |

You should always think about safety when you put in or take care of your solar system.

The 85°C limit is very important for solar panel safety. If panels get hotter than this, fire risk goes up and they work less well.

Check your solar panels often to see if they are too hot. Make sure air can move around the panels to keep them cool.

Pick solar panels with a low temperature coefficient. This helps stop power loss when it is hot outside.

Always check the fire ratings before you buy solar panels. Class A ratings give the best safety from fire dangers.

Make a plan for taking care of your solar panels and for emergencies. This keeps your solar system safe and helps you act fast if there is a problem.

It is important to know why the pv 85 c threshold is needed for safety. Solar panels should last a long time after you put them in. On hot days, the temperature of the module can go up fast. This happens more if there is not enough air moving around the panels. When the temperature gets to 85°C, the materials inside pv modules start to wear out much quicker.

Scientists use special tests to check how pv modules handle high heat. They keep the modules at 85°C with 85% humidity for many hours. These tests help show what could happen in years, but in just weeks. The table below shows what experts learned from these tests:

| Evidence Type | Description |

|---|---|

| Accelerated Aging Test | Damp-heat testing at 85°C and 85% relative humidity is a common method to assess PV module degradation. |

| Observed Phenomena | Darkening of cells in electroluminescence imaging due to metallization corrosion. |

| Degradation Mechanism | Acetic acid formation from EVA leads to corrosion of the glass layer and increased series resistance. |

| Performance Analysis | Current-voltage measurements and electroluminescence imaging were used to analyze degradation. |

These results show that the pv 85 c benchmark is very important. It marks the point where damage can happen much faster. Keeping your solar panels cooler than this helps them last longer and work better.

High temperatures do more than lower performance. They also make fires more likely. If a solar module gets too hot, it can catch fire more easily. Studies in labs show that when heat goes up, fire can start much faster. The table below shows how quickly fire can begin when pv modules get very hot:

| Heat Flux (kW/m²) | Ignition Time (s) |

|---|---|

| 28 | 913 |

| 45 | 83 |

| 26 (CHF) | N/A |

You can see that higher heat flux means fire starts sooner. If pv modules get too hot, the inside parts can break down. This can cause power loss, short circuits, or even flames. When modules get very hot, plastic parts may melt or burn. The glass can break, and metal parts can rust. These problems make the solar system less safe.

You should check your solar panels often for overheating. Make sure you set them up so air can move around each module. This helps keep them cool and lowers fire risk. If you live where it is very sunny and hot, watch the pv 85 c limit closely. Keeping your solar system cool keeps your home safe and helps your panels last longer.

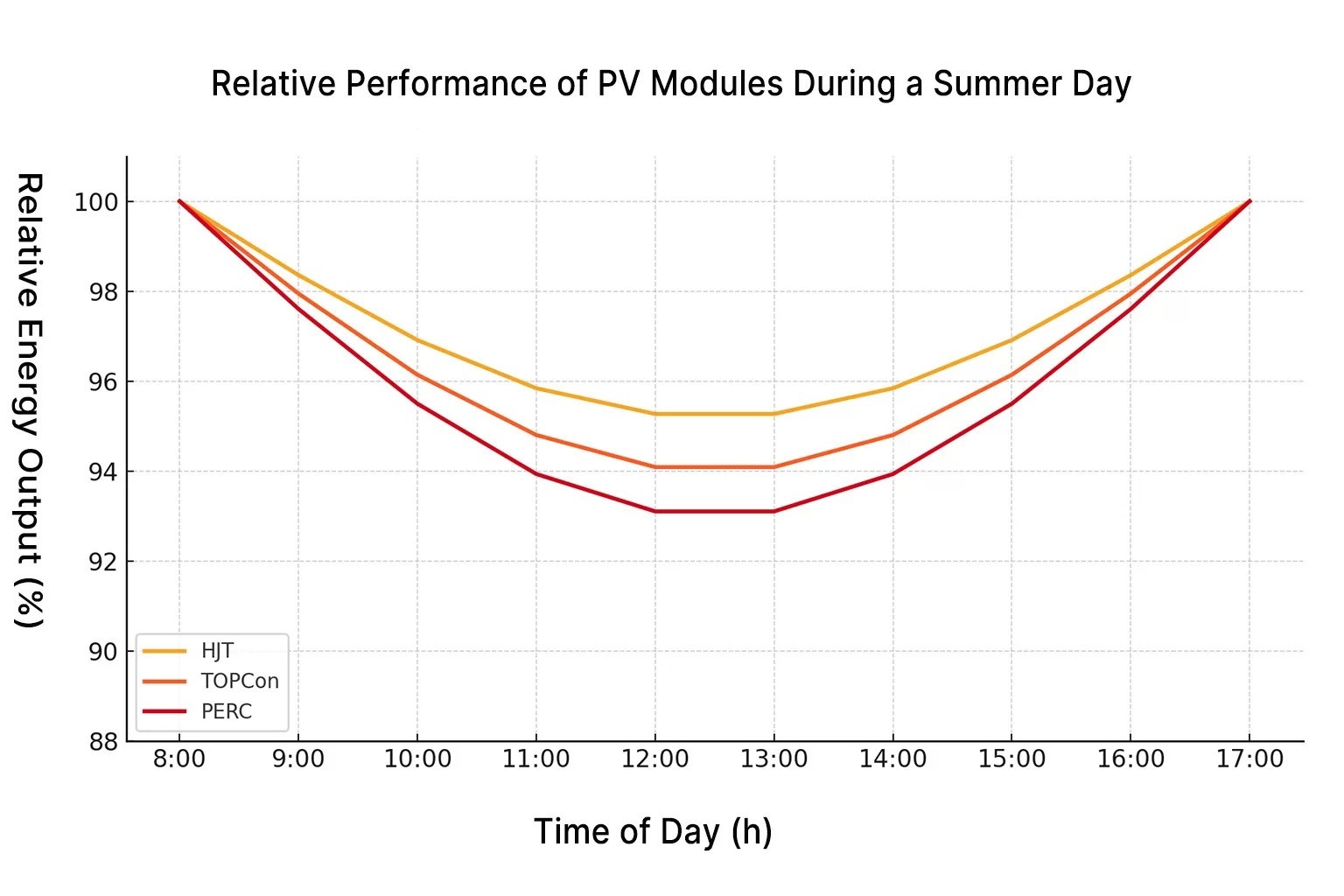

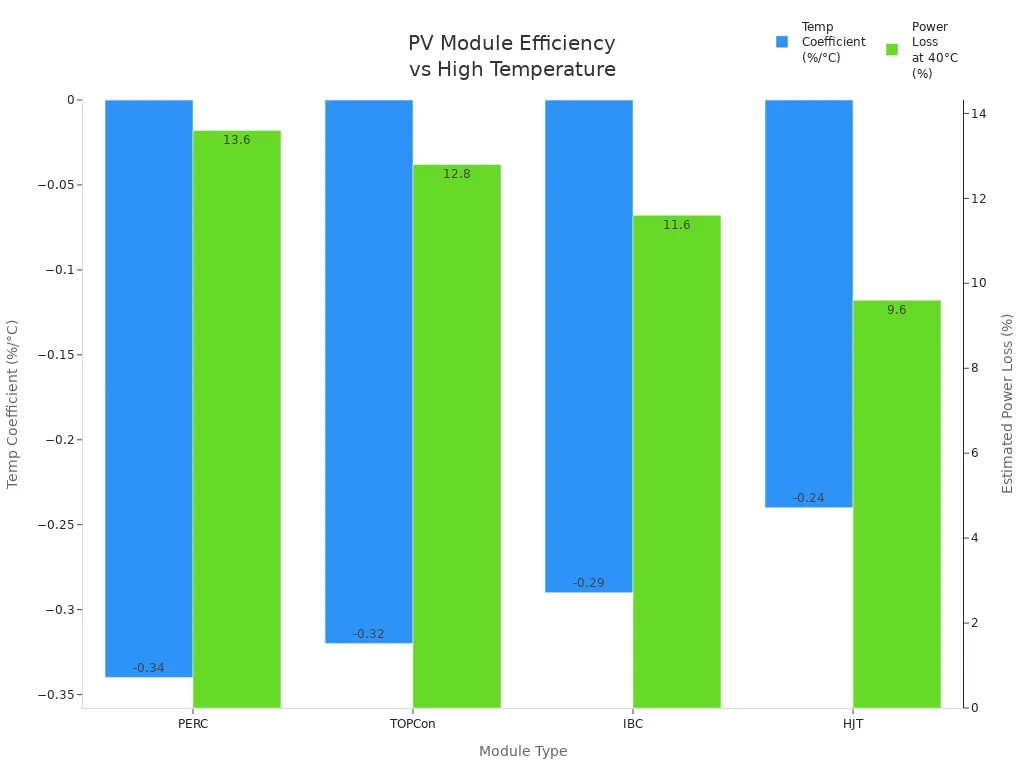

It is important to know how heat changes solar panels. When the module gets hotter, it makes less power. This is because the materials inside do not work as well when hot. The table below shows how different solar technologies lose power in heat:

| Module Type | Temperature Coefficient (%/°C) | Estimated Power Loss at 40°C Rise |

|---|---|---|

| PERC | -0.34 | About 13.6% loss |

| TOPCon | -0.32 | About 12.8% loss |

| IBC | -0.29 | About 11.6% loss |

| HJT | -0.24 | About 9.6% loss |

If you put solar panels in a hot place, you will lose more power. The temperature of your pv modules is very important. You should look at the temperature coefficient before picking a module. A lower coefficient means less power loss when it gets hot.

You want your solar system to work for many years. High heat and humidity can hurt pv modules over time. The damp heat test puts modules at 85°C and 85% humidity for 1,000 hours. This test shows how modules handle tough weather, like in hot and wet places.

The table below shows what happens to glass-glass modules in these conditions:

| Degradation Type | Observations |

|---|---|

| Corrosion | Noted as a significant factor affecting glass-glass modules under high temperature and humidity. |

| Delamination | Occurred due to prolonged exposure, leading to potential electrical insulation failures. |

| Power Loss | Up to 11% loss reported, indicating severe impact on module performance. |

| Bubble Formation | Linked to poor lamination quality, exacerbated by high humidity conditions. |

| Electrical Arcing Risk | Increased risk due to reduced insulation between components, potentially leading to fire hazards. |

If your modules face heat and humidity for a long time, you may see corrosion and delamination. These problems can lower power and make your system less safe. Bubbles and electrical arcing risk can also go up, which may cause fire.

Thermal cycling also changes how long modules last. When it gets hot and then cold, parts inside move and stretch. This can break solder bonds and cause stress. The table below shows how power drops after many cycles:

| Cycle Count | Power Degradation |

|---|---|

| 200 cycles | 3.5% |

| 400 cycles | 4.5% |

| 600 cycles | 5.3% |

Tip: Check your solar panels often, especially if you live somewhere hot. Look for corrosion, delamination, or bubbles. These issues can lower power and raise fire risk.

You can see that the temperature of your pv modules affects how long they last. If you keep your solar panels cool and dry, they will work better and be safer. The damp heat test shows that good modules can last over 25 years. Pick modules that pass this test to protect your money and your home.

It is important to know the main solar panel safety rules. These rules help keep your solar system safe and working well. The most important rules for fire and heat tests are IEC 61215, IEC 61730, and UL 1703. Each rule tells you what solar panels must do to be safe. The table below shows what each rule checks:

| Standard | Focus Area |

|---|---|

| IEC 61215 | Quality and safety of PV modules |

| IEC 61730 | Module safety, fire resistance, and temperature testing |

| UL 1703 | Safety and performance criteria for PV modules in North America |

Many solar panels have the IEC 61215 mark. This means the panel passed tough tests for safety and quality. In the USA and Canada, UL 1703 is used a lot. These rules check fire safety, heat tests, and other safety needs. When you pick a solar panel, look for these marks to make sure it follows all the rules.

Fire resistance is very important for solar panel safety. You want your solar panels to have the best fire rating for your area. Most places use IEC 61730 to check fire safety. In North America, UL 61730 uses both UL 1703 and IEC 61730 for even stronger rules. There are three main fire ratings:

Class A: Best fire rating, good for places with high fire danger.

Class B: Medium fire rating, works for many homes.

Class C: Basic fire rating, used where fire risk is low.

Fire ratings show how well a panel can stop fire and heat. Always check the fire rating before you buy or put in a solar panel. The label on the panel will show the fire rating and other key facts. IEC 61730 and UL 1703 both say the label must show the fire rating and safety class.

You should also think about what to do in an emergency. Module disconnects help firefighters turn off the pv system fast. This lowers the chance of electric shock and helps them fight fires safely. Good labels and easy-to-find disconnects help people act quickly in an emergency.

Tip: Always make sure your solar panels meet the newest fire safety rules and have clear labels. This helps you follow the law and keeps your home safe.

You must pick good materials for your solar modules. The fire resistance depends on the encapsulant and backsheet. EVA encapsulant keeps water away from solar cells. It also helps make the module safer. Polyester or PVF backsheets give insulation and keep water out. This makes fire resistance and thermal performance better. Modules with Class A fire rating protect the most. They meet tough standards like UL 61730-2 and UL 790.

| Fire Rating | Description | Testing Standards |

|---|---|---|

| Class A | Highest fire resistance, suitable for high-risk areas | UL 61730-2, UL 790 |

| Class B | Moderate fire resistance | UL 61730-2, UL 790 |

| Class C | Lowest fire resistance | UL 61730-2, UL 790 |

Tip: Always look for certification labels on your solar modules. These labels show the modules meet fire resistance and safety rules.

You can lower fire risk by using smart installation steps. Pick modules with a thicker backsheet, at least 300 micrometers. This helps with fire resistance. Lighter-colored modules soak up less heat. This keeps the temperature lower. Follow local rules for solar panel safety. Keep space clear around your solar system. Take care of plants nearby to stop fires. Put electrical gear in fire-resistant boxes. Use wires underground when you can.

Do a risk check before you install pv modules.

Make a wildfire emergency plan.

Put in and label a rapid-shutdown system for emergencies.

Teach local fire crews about your system’s safety needs.

Regular care keeps your modules safe. Use thermal imaging to find hot spots in warm months. Clean modules often to stop dust from building up. Dust can make modules overheat. Pick modules with lower temperature coefficients. This helps with safety and efficiency.

Electrical design choices change fire safety in pv systems. Good string setup and inverter choice stop overheating. Use the right wire size to keep insulation from melting. Put in arc-fault circuit interrupters (AFCIs) to catch and stop dangerous DC arcs. DC arcs get very hot and can start fires. The National Electric Code says AFCIs are needed for systems over 80 V DC.

| Requirement | Description |

|---|---|

| Energized Electrical Lines | Labels must show energized lines to stop cutting in emergencies. |

| Marking Conduit | Mark every 10 feet and at every turn so it is easy to see. |

| Label Visibility | Use white letters on red, at least 3/8″ tall. |

| Reflective Properties | Labels should be easy to see in low light. |

| UL969 Compliance | Labels must follow UL969 standards. |

Note: Clear labels help emergency workers find switches and voltage levels fast. This meets safety rules and helps in emergencies.

You can keep your solar system safe by watching module temperatures. Try to keep them under the pv 85 c benchmark. Check your panels often and use temperature sensors. This helps you find problems early. Install your system the right way and use fire-resistant materials. These steps lower the chance of fire. Watch both the air and module temperatures. This lets you act before heat causes damage. Follow pv safety rules to avoid fines or insurance trouble. Use this table to help plan what to do next:

| Action | Benefit |

|---|---|

| Annual maintenance | Keeps modules reliable |

| Risk assessment | Reduces fire hazards |

| Emergency plan update | Improves response |

If your PV modules get hotter than 85°C, you may see faster wear, lower power, and higher fire risk. You should check your system often and keep it cool to stay safe.

You can help your panels stay cool by allowing air to flow around them. Clean them often and remove anything that blocks airflow. Pick light-colored panels if you live in a hot area.

Fire ratings show how well your panels resist catching fire. You should always choose panels with a Class A rating for the best protection, especially if you live in a place with high fire danger.

Turn off your system right away.

Call a certified solar technician.

Do not try to fix the panels yourself.

You keep your home safe by acting quickly.

Yes, you need clear labels and easy-to-find disconnects. These help firefighters shut down your system fast in an emergency. Labels must follow safety rules and be easy to read.

Comprehensive Guide to Fire Safety in Photovoltaic Systems: Prevention, Risks, and Best Practices

PV Professional's Technical Analysis: Optimizing Polycrystalline Panel Installation and Maintenance

Integrating Polycrystalline Panels in PV Carport Structures: Design Considerations and Benefits

Choosing the Right PV Backsheet Materials to Minimize Cleaning Needs and Maximize Performance