Views: 0 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

PV Bonding Materials are important for protecting solar panels. They keep out bad weather, dust, and water. These materials help stop moisture from getting inside. They also help prevent metal parts from rusting. The panels do not wear out too fast. Picking the right materials is important. Using them the right way helps solar panels last longer. It also helps them work better.

PV Bonding Materials keep solar panels safe from rain and dust. They also protect panels from moisture. This helps panels last longer. It helps them work better too.

Good bonding materials stop water and dirt from getting in. This makes panels work better. It helps them make more electricity.

Checking and fixing solar panels often can find problems early. This helps panels work well for a long time.

Using the right encapsulants, backsheets, and adhesives makes panels stronger. It helps panels work better.

Picking materials that pass tough tests is very important. These tests check for UV, water, and heat resistance. This helps solar panels last longer.

PV Bonding Materials help solar panels last longer. Good materials protect panels from rain, wind, and dust. They keep the inside parts safe from harm. Strong materials help panels survive bad weather.

Mechanical load testing checks if panels can handle heavy snow or strong wind.

Static load testing puts steady weight on panels to see if they hold up.

Dynamic load testing uses changing forces, like wind gusts, to see if panels stay strong.

Panels with good bonding materials do not crack or break easily. They do not bend much and keep their shape. This helps panels last for many years without big problems.

Note: Panels with weak bonding materials may break early. Cracks, leaks, or broken seals can let water in and cause rust or other damage.

The right PV Bonding Materials help solar panels work better. Good materials keep out water and dirt. They stop air from getting inside the panel. This keeps the electrical parts safe and working well.

When panels stay dry and clean, they make more electricity. If water or dust gets inside, the panels lose power. The energy output drops, and the panels do not work as well.

A table below shows how different bonding materials can affect panel efficiency:

| Bonding Material Quality | Panel Efficiency | Risk of Damage |

|---|---|---|

| High | High | Low |

| Medium | Medium | Medium |

| Low | Low | High |

Panels with high-quality bonding materials keep working well for a long time. They do not lose power fast. This helps people get more value from their solar panels.

Encapsulants keep water, dust, and stress away from solar cells. They make a clear layer that covers and protects the cells. Some common types are ethylene-vinyl acetate (EVA) and polyolefin elastomer (POE). These materials help stop damage as time passes. Encapsulants also block harmful UV rays and help control heat inside the panel.

| Aspect | Description |

|---|---|

| Thermal Stabilizers | Stop heat from hurting encapsulants during making and when it gets hot or cold. |

| UV Absorbers | Turn bad UV light into safe energy, so the material does not get hurt. |

| UV Stabilizers | Catch radicals and stop color changes or losing clearness. |

| Moisture Protection | Make a strong wall against water, so no rust or cell harm happens. |

| Thermal Management | Keep the temperature steady, so the panel does not get stressed. |

Encapsulants keep the inside dry and clean. This helps solar cells work well for many years.

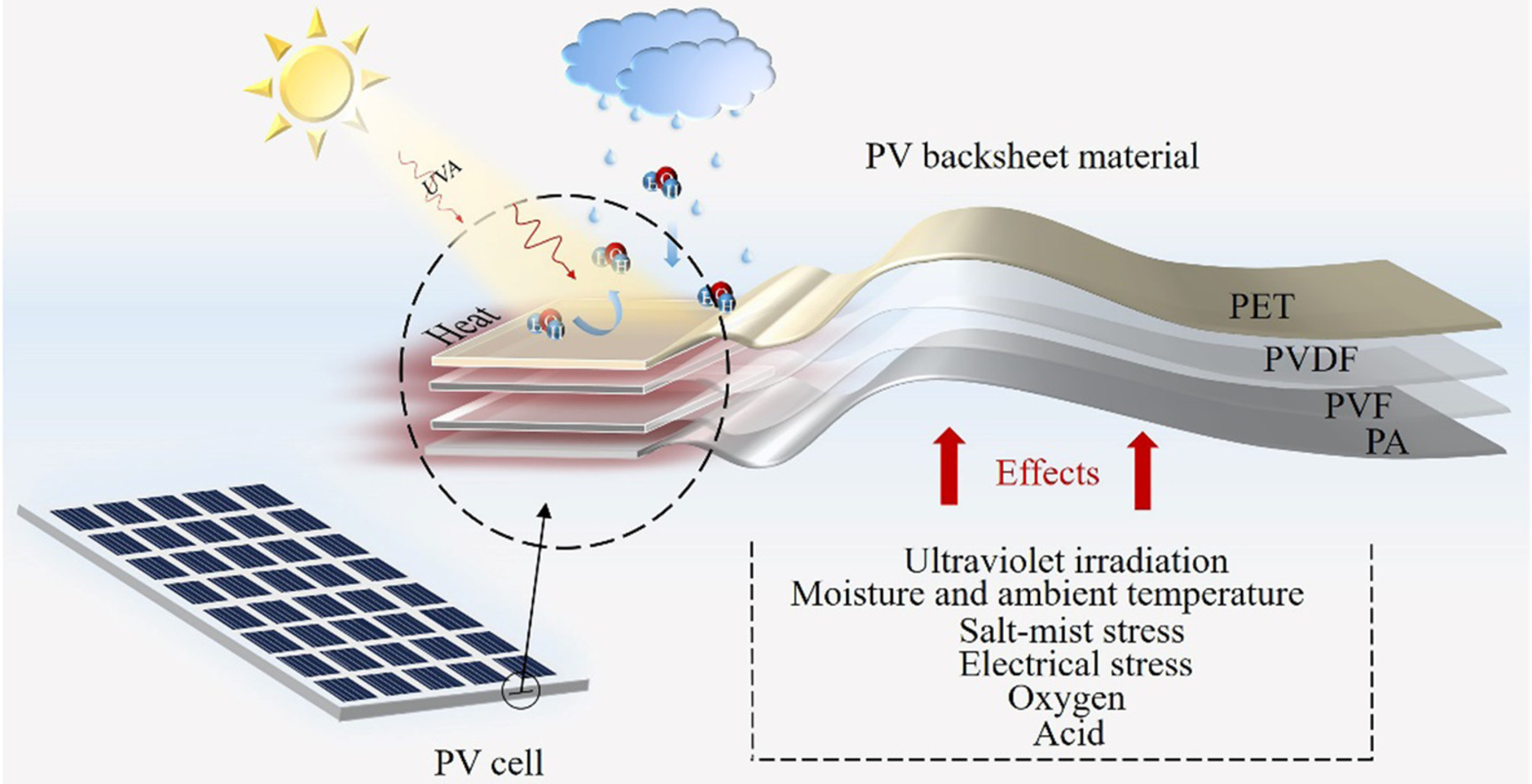

Backsheets cover the back part of the solar panel. They protect the panel from sun, water, and dirt. Good backsheets stop water from getting in and block UV rays. Two common kinds are TPT and PVDF. Each one gives a different level of protection.

| Material | UV Resistance | Moisture Barrier |

|---|---|---|

| TPT | 8/10 | 9/10 |

| PVDF | 9/10 | 8/10 |

TPT backsheets are very good at stopping water. PVDF backsheets are great at blocking UV rays. Both types help panels last longer and keep working well.

Sealants and adhesives hold solar panel parts together. They also seal the edges to keep out water and air. Silicone adhesives and silicone gel are used a lot. These materials can handle chemicals, water, and bad weather. Using edge sealants can make it take twice as long for water to cause harm. Panels with edge sealants stay dry much longer and keep making power for many hours.

Silicone adhesives and sealants make strong holds and stand up to tough weather.

Edge sealants help panels last 10 to 15 years longer.

Desiccated sealants slow down water damage and help panels work in hot places.

PV Bonding Materials like these protect solar panels and help them work well for a long time.

Solar panels can have many problems over time. Most problems come from weather and using bad materials. If PV Bonding Materials do not work well, panels lose power and stop working early.

Water can get inside if seals or backsheets are weak. This water causes chemical changes inside the panel. These changes make acids and other bad things. Metal parts start to rust, and lead rusts faster than tin. As rust spreads, the panel loses about 1.2% of its power each year. After a while, the metal parts may stop working.

| Findings | Description |

|---|---|

| Degradation Products | Water makes acids and gases that hurt the metal parts. |

| Metal Ion Migration | Water helps metal ions move and cause more rust. |

| Corrosion Preference | Lead rusts faster than tin when water is around. |

| Performance Impact | Power drops about 1.2% each year from rust. |

Panels in wet or salty places break down faster. Bad backsheets and adhesives let in more water, making damage happen quicker.

Delamination means the layers inside the panel peel apart. Heat, water, and stress make this worse. If the bonding materials are not good, they cannot keep the layers together. This makes gaps and bubbles inside the panel. Hot and wet weather or freezing can make the glue fail. When delamination starts, the panel gets weaker and loses power.

Heat and cold can crack solder bonds and cells.

Wet heat can make the encapsulant peel off.

Humidity and freezing can break the bond at the junction box.

Sun and heat can hurt the materials in a solar panel. UV rays from the sun turn the clear layer yellow. This yellow color blocks light and lowers power. Heat makes tiny cracks in the silicon cells. Over time, these cracks get bigger and lower the panel’s output. UV rays also break down coatings and adhesives, making the panel weaker.

UV rays turn the clear layer yellow and block light.

Heat makes tiny cracks in the cells.

Damaged coatings let in more water and dirt.

Tip: Using good bonding materials helps panels fight these problems and last longer.

Solar panels deal with tough weather all the time. Good PV Bonding Materials need to handle strong sun, rain, and heat. Some materials get weak if they get too much UV light. This can make the glue stop working and the panel lose power. Water can sneak in and make the bonds weaker. This can cause rust and other problems.

Key things to remember when picking materials for hard weather:

UV rays can make adhesives hard and easy to break.

Water can make adhesives weaker and cause them to fail.

Thermoset materials stand up to UV light better than thermoplastics.

Thermoplastics break down faster in the sun.

| Criteria | Description |

|---|---|

| UV Resistance | Thermosets are better at blocking UV because of crosslinking, so they are harder to break down. |

| Degradation Rate | Thermoplastics break down faster in UV light than thermosets because they have smaller molecules. |

Silicone adhesives and strong backsheets help panels last longer in wet or sunny places.

Not every bonding material works with every solar cell. Using the wrong one can cause rust or weak bonds. The washer in a solar panel should match the rack material. This helps stop rust and keeps the panel strong.

| Factor | Importance |

|---|---|

| Material Match | Stops rust and makes panels more reliable |

| Stability | Helps panels last longer and work better |

Installers should always check if the bonding material fits the panel. This helps stop early problems.

Panels that last a long time need strong bonding materials. Good PV Bonding Materials keep their strength for many years. They do not get weak from sun, heat, or water. Silicone adhesives and tough backsheets do well in many tests. These materials help panels work well for a long time.

Tip: Always pick materials that pass hard tests for UV, water, and heat. This helps protect your solar panels.

Solar panel makers do lots of tests to check bonding materials. These tests show if the materials can handle weather and stress. One test is called the adhesion test. It checks how well the layers stick together. If the peel force is low, the panel might not last long. If the peel force is high, the panel stays strong and works better.

| Adhesion Test Condition | Peel Force (N/mm) | Real-World Performance Impact |

|---|---|---|

| Laminated at 150 °C with EVA | 0.045 | Low performance at first |

| Enhanced with surface treatment and higher temp | 1.70 | Much better adhesion and performance |

| POE encapsulant adhesion | >6.0 | Similar to other high-performance materials |

Other tests use heat, light, and moisture for many hours. Makers also use thermal cycling to see if materials crack or peel when temperatures change quickly. These tests help find weak spots before panels go outside.

Tip: Panels that pass these tests are more likely to last longer and keep making power.

Regular checks help find problems early. If someone sees cracks, bubbles, or yellow spots, they can fix the panel before it stops working. Experts say to check solar panels at least twice a year. Looking at the panels every few months helps spot small problems. A professional should inspect the panels every three years to keep the warranty good.

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Inspect solar panels | At least twice a year | Find safety issues early |

| Visual checks | Quarterly | Spot problems early |

| Professional inspections | Every 3 years | Keep warranty valid and follow rules |

A good maintenance plan keeps your investment safe. PV Bonding Materials that pass tough tests and get regular checks help solar panels work well for many years.

PV Bonding Materials help solar panels last longer and work better. Good materials like POE, TPO, and ionomers are stronger against damage. POE does not break down easily. TPO lasts longer and can be recycled. Ionomers keep out water and block UV rays.

| Material Type | Benefits |

|---|---|

| POE | Does not break down easily |

| TPO | Lasts longer and can be recycled |

| Ionomers | Blocks water and UV rays |

New things like special coatings and amidinium ligands help panels stay strong and make more power. Industry rules like IEC 61215 and IEC 61730 test panels to make sure they are safe and work well. These rules check if panels can handle bad weather. Certification means panels follow safety and work rules. Warranties help buyers if something goes wrong and promise the panels will work well.

People should pick good materials, put them in the right way, and learn about new ideas to keep their solar panels safe.

PV bonding materials help keep solar panels safe. They stop water, dirt, and sunlight from getting inside. These materials help the panels last longer. They also help the panels work better.

Experts say to check solar panels two times each year. Checking often helps find cracks, bubbles, or yellow spots early.

| Material | Water Resistance | UV Protection |

|---|---|---|

| POE | Excellent | Good |

| Silicone | Very Good | Very Good |

| TPT | Good | Good |

POE and silicone are good choices for wet places.

Tip: Bad bonding materials let water and dirt get inside. This can make the panel create less electricity. Good materials help panels work their best.

PV System Troubleshooting: Why Starting with Module EL Inspection Reveals Hidden Performance Issues

Electroluminescence (EL) Inspection for Solar PV Modules: Detection, Analysis, and Quality Assurance

2025 Half-Cut Solar Panel Market Analysis: Trends, Growth Projections, and Leading Manufacturers

Agrivoltaics: The Complete Guide to Combining Solar Energy and Agriculture for Sustainable Farming

Agri-PV Systems: Benefits, Implementation Strategies, and Real-World Success Stories