Views: 0 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

Photovoltaic adhesives keep the solar panel parts together. They also help move energy in the panel. You need the right adhesive to make panels strong and safe. Photovoltaic adhesives must last through bad weather. They also need to keep working for a long time. Picking adhesives with the best properties helps your system work better. Good choices also protect high-efficiency pv cells. Look for strength, thermal stability, and conductivity. These things help your photovoltaic adhesives work well.

Picking the right photovoltaic adhesive is very important for solar panel strength and how well they work. It helps keep panels safe from bad weather and UV rays.

Find adhesives that let electricity flow well. This helps power move better between solar cells and makes them work better.

Think about how strong the adhesive is. Strong glue stops the layers from coming apart and keeps panels together in tough weather.

Choose adhesives that can handle heat. They should not stop working when it gets hot, so the panels last longer.

Check if the adhesive can resist things in the environment. The right glue will protect panels from water, sun, and rust, so they last longer.

![]()

Photovoltaic adhesives help keep solar panels together. They do more than just stick parts. These adhesives make building panels easier. You do not need many screws or bolts. This means less stress on the panels. The right adhesive protects modules from bad weather and sunlight. It stops water from getting in. It also blocks harmful UV rays. This helps panels work better and last longer.

Tip: Picking the right adhesive can help the environment. Some adhesives work at lower temperatures. You use less energy and avoid lead.

Here is a table that shows what photovoltaic adhesives do:

| Function | Description |

|---|---|

| Cost Reduction | Makes solar panels cheaper to build and install. |

| Simplified Manufacturing Process | No need for extra fasteners, so building is easier. |

| Enhanced Performance | Gives good thermal and electrical control, UV protection, and lasts a long time. |

| Environmental Protection | Cuts pollution and gets rid of lead by using lower temperatures. |

There are different types of adhesives for solar panels. Each type has special features. Some common ones are:

POE adhesive film uses POE resin and protects against water and aging.

Some advanced adhesives are conductive. They use epoxy-urethane acrylate resin and silver flake-glass particles. These work well in shingled and ribbon-attached modules. They give high conductivity with less silver.

Here is a table with more examples:

| Adhesive Type | Composition | Key Features |

|---|---|---|

| Epic S7469 | 2-Component Urethane | Cures fast and sticks well to plastics. |

| Epic S7459 | 2-Component Thixotropic Polyurethane | Gels quickly and seals metal and plastic. |

| Epic D9960 | 2-Component Aliphatic Polyurethane | Resists UV, is flexible, and works for gaskets. |

| Electrically Conductive Adhesive | Epoxy-Urethane Acrylate with Silver Fillers | Conducts electricity well and works for special modules. |

Always pick the adhesive that fits your panel’s needs. Check for strength, weather resistance, and easy use. This helps your photovoltaic system last longer and work better.

When you pick an adhesive for solar panels, you must check some important things. You need to think about conductivity, strength, and how long it lasts. If you get the balance right, your solar panels will work well for many years. New adhesives, like silicone adhesives and nanocomposites, help high-efficiency cells do better. Here are the main things you should look at.

Adhesives should let electricity move easily between the parts. Electrically conductive adhesives help send power from the cells to the rest of the system. If you use a water-based adhesive with silver micro-flakes, your panel can make more power. The table below shows how these adhesives work:

| Metric | Value |

|---|---|

| Volume Resistivity | 22 μΩ/cm |

| Adhesive Yield Stress | 4.8 MPa |

| Increase in Power Conversion Efficiency | 0.4% (absolute) |

| Adhesive Type | Water-based with silver micro-flakes |

Most conductive adhesives in photovoltaic modules try to have volume resistivity lower than 10^-4 Ω·cm. This low resistivity helps your panels work better. You also want shear strength higher than 20 MPa and thermal conductivity over 3 W/m·K. These numbers help your solar panels make more energy.

Strong adhesives keep solar panels together, even when the weather is bad. High mechanical strength means the adhesive holds parts tight. It also spreads out stress, so one spot does not get too much pressure. This stops cracks or breaks from happening. The table below explains why strength is important:

| Property | Description |

|---|---|

| High mechanical strength | Strong bonds can be even better than screws or bolts. |

| Material Bonding | Adhesives join different materials and keep them stable. |

| Uniform stress distribution | Stress spreads out, so panels do not fail easily. |

| Impact resistance | Panels can handle shocks and outside forces. |

You also need to think about the backsheet of your solar panel. The backsheet protects the inside parts and gives electrical insulation. If the adhesive does not work, the whole panel might stop working well. Industrial adhesives help you build panels faster and make them last longer.

Solar panels get hot when the sun is out. You need adhesives that can handle high heat and still work. Silicone adhesives are a good choice. They stay flexible from -60 to 200 ℃. They also do not break down in sunlight or bad weather. Here is a table that shows what thermal stability means for your panels:

| Property | Description |

|---|---|

| Temperature Range | Silicone adhesives work from -60 to 200 ℃. |

| UV and Ozone Resistance | They last a long time in sunlight and bad weather. |

| Weathering and Aging Resistance | They keep working, even after years outside. |

| Impact Resistance | They help your panels stay safe and strong. |

Silicone adhesives keep your panels sealed and stuck together, even in very hot weather. This helps your photovoltaic system last longer.

You want your solar panels to last for many years. Durable adhesives keep water, dust, and dirt out. They also stop the panels from coming apart. Good sealing means you do not have to clean or fix them as much. The table below shows how durability helps your panels:

| Evidence Description | Impact on Solar Panel Performance | Maintenance Requirements |

|---|---|---|

| Adhesives seal edges and joints, keeping out water and dirt. | Panels last longer. | Less maintenance needed. |

| Strong sealing solutions work for decades, even in harsh places. | Panels stay efficient. | Fewer repairs needed. |

If the adhesive gets weak, the panel can start to peel apart. This is called delamination. Delamination can make your panels unsafe and not work as well. It often happens when water or heat makes the bond weaker. Using the right adhesive helps you stop these problems and keeps your panels working well.

Note: If you pick adhesives with the right properties, your solar panels will stay efficient and reliable for a long time.

You should always check if the adhesive works with your materials. The adhesive needs to stick well to glass, polymers, and metals. If you do not check, the bond might be weak. Weak bonds can cause the panel to break or peel apart. This is called delamination. Always test the adhesive with your solar panel parts. Some adhesives, like electrically conductive adhesives, work best on certain surfaces. When you pick the right adhesive, you get strong bonds and better sealing.

| Criteria | Description |

|---|---|

| Environmental Conditions | Think about UV, temperature, moisture, and chemicals when you pick an adhesive. |

| Compliance with Industry Standards | Make sure your adhesive meets IEC, RoHS, and REACH rules. |

| Curing Process | Pick a curing method that fits your process, like UV or heat. |

| Longevity | Look for adhesives with long-lasting properties and weather resistance. |

| Material Compatibility | Test with glass, polymers, and metals for best results. |

Solar panels outside face many tough things. You need adhesives that can handle humidity, ultraviolet rays, corrosion, and particle radiation. These things can make the panel change color, peel, or even break. Good sealing keeps water and dirt out of your panels. Strong sealing helps your solar panels work longer.

Humidity

Particle radiation

Ultraviolet rays

Corrosion

Delamination

Tip: Humidity and UV rays can change how much light your panel gets. They can also lower current and cause optical losses.

There are different ways to put adhesives on solar panels. You can use a roller, spray, or jet system. Each way changes how well the adhesive covers the parts. Using special tools and watching closely helps you get an even layer. Even layers make the seal better and help your panels last longer. If you use conductive adhesives, make sure you cover everything evenly for the best results.

You need to think about both cost and performance. Some adhesives cost more because they last longer or work better. Electrically conductive adhesive may cost more, but it can help your panels work better. Always look at the total value, not just the price. Good sealing can save you money on repairs and fixing your panels later.

Picking the right adhesive helps your solar panels work better. Electrically conductive adhesives let electricity move between cells. These adhesives use special materials like silver nanowires and carbon nanotubes. This gives better conductivity and makes the panels more flexible. Some adhesives mix with soldering to make panels stronger in tough weather. Eco-friendly and lead-free adhesives are good for the environment. New adhesive formulas help panels handle heat and stick well. Here are some ways adhesives help electrical performance:

Electrically conductive adhesives make panels conduct electricity better.

Silver nanowires and carbon nanotubes help panels bend and work well.

Eco-friendly adhesives help you follow the rules for the environment.

Hybrid adhesives with soldering make panels last longer in bad weather.

New formulas help panels stay strong and handle heat.

Using advanced conductive adhesives helps your panels make more power. These adhesives stop small cracks and let you use more of the panel’s surface. Your solar panels make more energy and last longer.

You want your solar panels to last a long time. The right adhesive keeps water out and stops damage from weather. Edge sealants block water and stop power loss. Studies show edge sealants can add 10 to 15 years to your panels. This means your panels last longer and need fewer repairs. Strong adhesives keep panels from peeling or breaking. Conductive adhesive films help panels handle heat and sunlight. You spend less time fixing your panels and get more energy.

Edge sealants keep water out and stop power loss.

Panels with sealants last longer and work better outside.

You can add up to 15 years to your panels’ life.

Conductive adhesive film helps panels handle heat and sunlight.

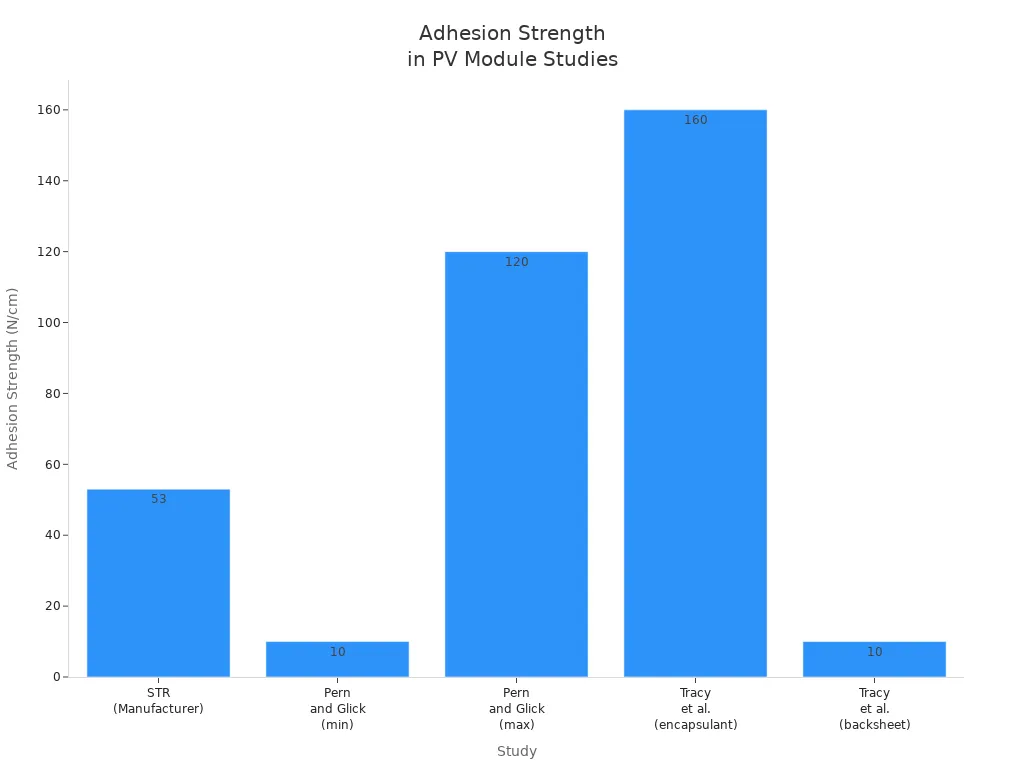

You can see how adhesives work in real-life tests. The table below shows how different adhesives change strength and durability:

| Study | Findings | Adhesion Strength (N/cm) | Notes |

|---|---|---|---|

| STR (Manufacturer) | Stops peeling for 20 years | 53 (minimum) | Good for long-term use |

| Pern and Glick | Glass and EVA stick together well | 10 to 120 | No set minimum value |

| Tracy et al. | New ways to test encapsulant and backsheet | 160 (encapsulant), 10 (backsheet) | Safety thresholds |

| Dadaniya and Datla | Model for strength loss | N/A | Focus on stress effects |

Advanced coatings and adhesives also help panels work better. These upgrades protect against sunlight, water, and heat. Coatings can make panels up to 30% more efficient. You get more energy, less work fixing panels, and longer-lasting solar panels.

| Performance Improvement | Description |

|---|---|

| Anti-fogging Property | Keeps panels clear in all weather |

| Enhanced Transmittance | Lets in more light and cuts down haze |

| Improved Coating Hardness | Makes panels tougher and helps them stick |

Tip: If you pick the best adhesive and coating, your solar panels will work better, last longer, and give you more energy.

If you pick the right adhesive, your solar panels work better and last longer. The adhesive must fit what your solar cells need. This helps stop heat problems and keeps power steady. New materials and conductive adhesives are coming out. You should look for ones that bend, block UV rays, and are easy to use. Rules check if adhesives burn, track electricity, and last a long time. Always check these rules before you choose. Keep learning about new technology to help your solar panels work their best.

A photovoltaic adhesive holds solar panel parts together. This glue keeps panels strong outside. It protects inside parts from water and dirt.

Conductive adhesives help electricity move between solar cells. They let panels send more power to homes or businesses. These adhesives also help panels last longer.

Check if the adhesive works with your panel materials. Look for strong bonds and weather resistance. Make sure it is easy to use. Always test the adhesive before using it everywhere.

Yes, adhesives can help panels work better. The right adhesive keeps panels sealed and safe. It stops water and dust from getting inside. This helps panels make more energy and last longer.

Choosing the Right PV Backsheet Materials to Minimize Cleaning Needs and Maximize Performance

Solar Panel Encapsulation Explained: Materials, Benefits, And Selection

Integrating Polycrystalline Panels in PV Carport Structures: Design Considerations and Benefits

What is the structure, form and advantages of On-grid solar system ?